Egg Tray Manufacturing Plant Paper Pulp Molding Machines

| Model | SL-3*4 |

| Capacity | 2000-2500pcs/h |

| Paper consumption | 200kg/h |

| Water Consumption | 450kg/h |

| Energy used | 58kw/h |

| Worker | 4-5 |

You can now ask our project managers for technical details

The egg tray manufacturing plant is an automated complete set of equipment that facilitates efficient and fast production of egg trays. It can make different forms of egg trays by changing molds. For example, egg tray, egg tray box, egg tray with color, apple tray, etc. Shuliy’s egg tray production line has been sold to many countries such as Nigeria, Bolivia, Cameroon, Colombia, Morocco, and Sri Lanka.

Raw materials used in the egg tray manufacturing plant

The raw material used to make egg trays is waste paper. For example, waste cartons, newspapers, books, magazines, and so on. The cost of these raw materials is low, very environmentally friendly, and helps to save resources.

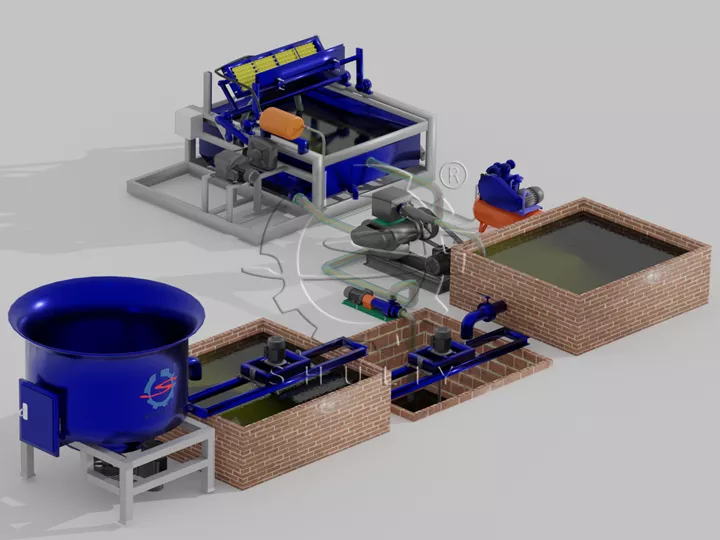

What are machines included in the paper tray production line?

The egg tray machine production line generally contains pulpers, egg tray machines, dryers, heat presses, balers, etc.

Pulping machine

This machine can process all kinds of waste paper into uniform and fine pulp. The high-quality pulp is directly related to the finished egg tray.

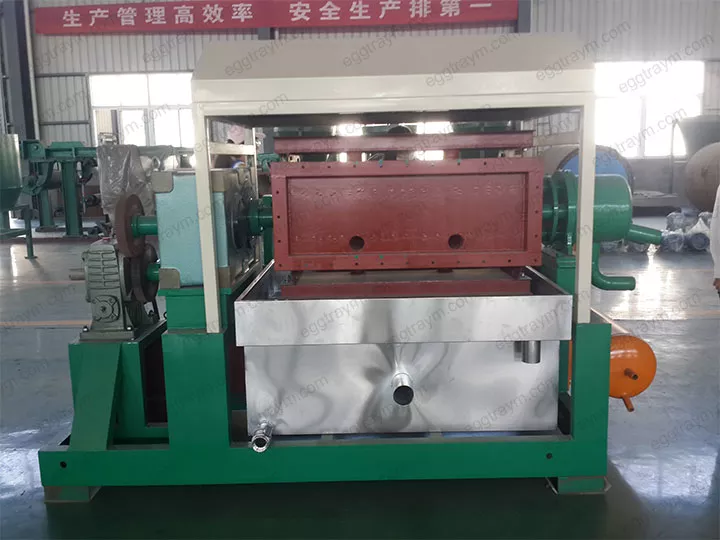

Egg tray forming machine

Our egg tray machine has many different models, customers can choose according to their needs. Besides, customers can change the molds according to their needs. We can also make customized molds for our customers.

Drying machine

We have different drying machines, there are brick kiln drying and metal drying. Different drying methods have different prices and different production efficiency.

Heat press machine

The hot press is good for helping the dried egg tray to be further shaped. After the hot press treatment, the egg tray is more tough and shaped.

Packaging machine

A baling machine is a machine that can squeeze the aged egg trays together. The use of this machine is good for carrying finished egg trays.

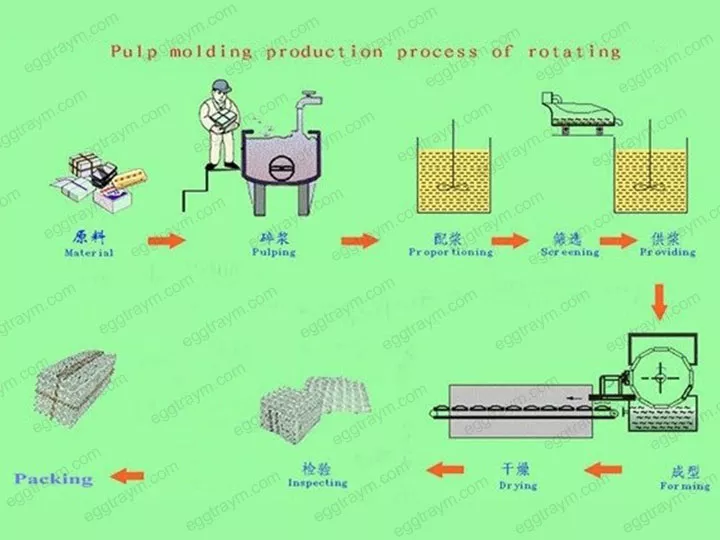

Workflow of egg tray manufacturing plant

The workflow of the egg tray manufacturing plant equipment is egg tray pulper, egg tray forming machine, drying, hot pressing, and packing. Due to the different matching of the egg tray production lines, the machine used in each part varies.

For example, the drying part can be a metal dryer, brick kiln drying, or natural air drying. If it is a semi-automatic egg tray machine, drying, hot pressing, and packing are all handled manually.

How does the egg carton production line work?

Parameters of complete paper carton production line

| Model | Capacity | Paper consumption | Water Consumption | Energy used | Worker |

| SL-3*1 | 1000-1500pcs/h | 120kg/h | 300kg/h | 32kw/h | 3-4 |

| SL-4*1 | 1500-2000PCS/h | 160kg/h | 380kg/h | 45kw/h | 3-4 |

| SL-3*4 | 2000-2500pcs/h | 200kg/h | 450kg/h | 58kw/h | 4-5 |

| SL-4*4 | 3000-3500pcs/h | 280kg/h | 560kg/h | 78kw/h | 4-5 |

| SL-4*8 | 4000pcs/h | 320kg/h | 600kg/h | 80kw/h | 5-6 |

| SL-5*8 | 5000pcs/h | 400kg/h | 750kg/h | 85kw/h | 3-4 |

| SL-5*12 | 6000pcs/h | 480kg/h | 900kg/h | 90kw/h | 3-4 |

| SL-6*12 | 8000pcs/h | 640kg/h | 1040kg/h | 100kw/h | 3-4 |

Advantages of paper pulp egg tray production line

- High efficiency of the paper pulp egg tray production line. For example, if the dryer is handled manually, it takes time to move the trays and time to dry the egg trays. Using a metal dryer can dry large quantities of egg trays at one time.

- The whole process is made by machine without error. All the egg tray-making process is done by machine. Therefore, errors that may be caused by manual operation are avoided.

- Easy to install. It is easy to install all the machines in the egg tray manufacturing plant.

- Save floor space. If the natural drying method is used, a large number of egg trays will take up a lot of space.

Shuliy full auto pulp egg tray production line

- Considerate service. We will answer any questions from customers in time. We will provide customers with sufficient information at every step of the process so that customers can buy with confidence.

- Suitable egg tray production line. The sales manager will recommend the right combination of an egg tray manufacturing plant according to the customer’s specific situation, such as budget, site size, output, etc.

- High-quality machines. Each machine is manufactured with high-quality raw materials. The long service life of the machine.

- One year after-sales service. Customers can contact us directly if they have any problems within one year of receiving the machine. We will help customers to solve the problem actively.

Egg tray machine production line sold to Colombia

A customer from Colombia wanted to build a new egg tray manufacturing plant. Since it was the first time the customer knew about the egg tray machine, our salesperson first sent pictures and videos of the machine to the customer. This will give the customer a general idea of the egg tray making machine.

Then we send the customer the parameters of all the egg tray machine models for the customer’s reference and selection. After that, according to the customer’s choice of machine model, we match the customer with the corresponding egg tray manufacturing plant. Finally, the customer and his partner discussed and decided to buy the egg tray machine line together.

If you are interested in egg tray production and waste paper recycling, please browse this website and feel free to contact us for more detailed information and quotations. We look forward to cooperating with you.