2000-2500PC/H Automatic Egg Tray Machine

| Model | SL-3*4 |

| Output | 2000-2500pcs/h |

| Paper consumption | 200kg/h |

| Water Consumption | 450kg/h |

| Energy used | 58kw/h |

| Work number | 4-5 |

You can now ask our project managers for technical details

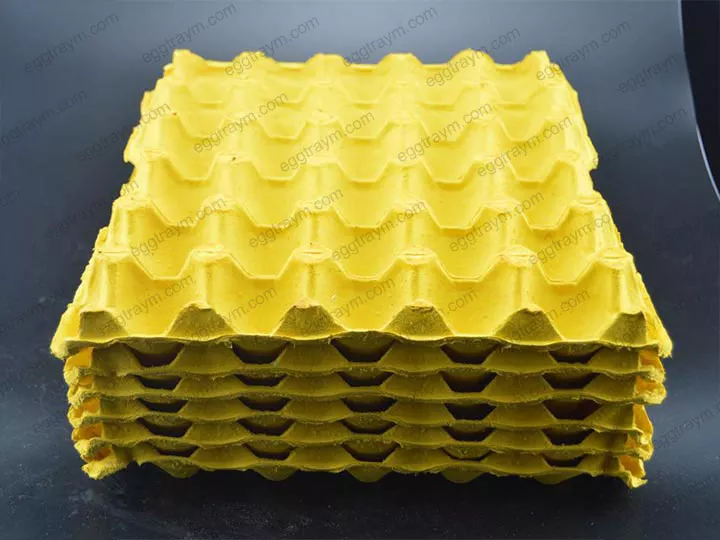

The automatic egg tray machine can manufacture paper trays of various shapes and colors. So it can meet people’s demand for different paper trays. Depending on your production scale and needs, our factory can produce machines with a variety of output models, and customize molds according to your finished products. Welcome to contact us!

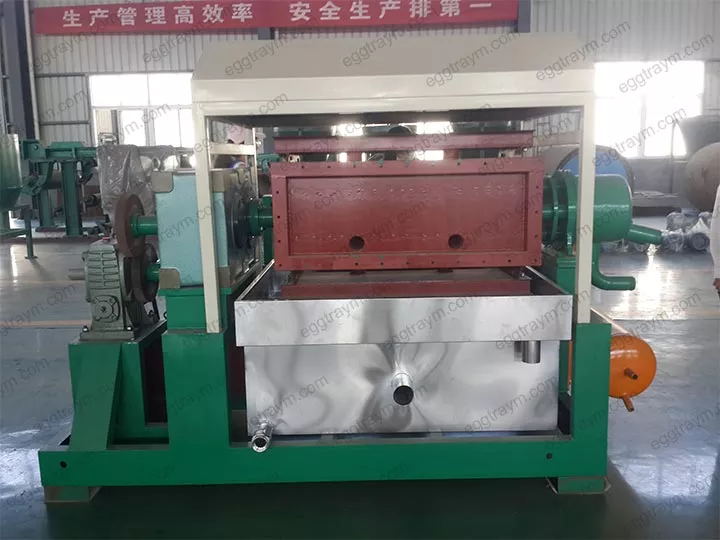

A brief introduction to automatic egg tray machine

Our SL-3*4 automatic egg tray machine is highly productive and can produce 2000-2500 pcs per hour. So it can meet the needs of larger factories. The powerful egg box-making machine can produce all kinds of egg trays. Also, our automatic egg tray machine is easy to operate, highly automated, energy-saving, and long life. Users can save a lot of labor and time.

Parameters of the egg carton making machine

| Model | Output | Paper consumption | Water Consumption | Energy used | Work number |

| SL-3*4 | 2000-2500pcs/h | 200kg/h | 450kg/h | 58kw/h | 4-5 |

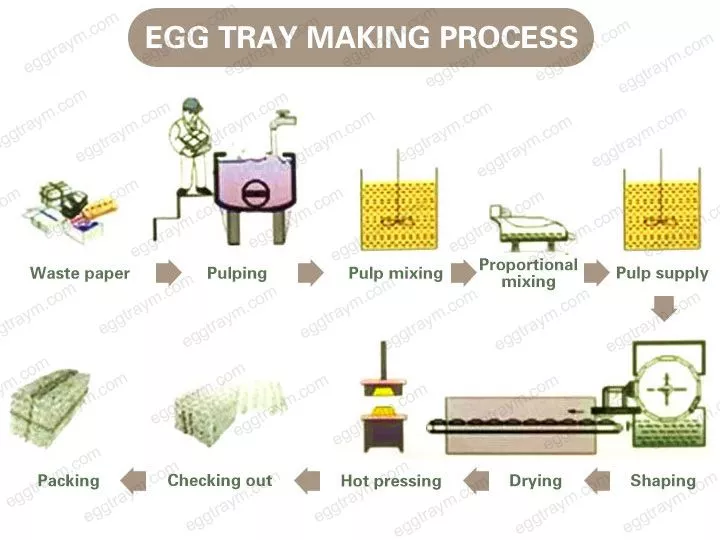

How does the paper egg tray making machine work?

Using scope of rotary egg tray machine

The raw materials for making egg trays and the scope of use are relatively wide.

Raw material: All kinds of recycled paper pulp.

Scope of use: The tray can pack eggs, fresh fruits, electrical appliances, fragile products, agricultural appliances, food packaging, medical appliances, etc.

Production process of the egg trays

The egg tray production line mainly includes a pulp-making machine, vacuum pump system, egg tray machine forming machine, egg tray drying machine, forming machine, egg tray packing machine, etc.

- First, add waste paper to the pulp shredder and add water.

- Then send the pulp to the pulp storage tank, and mix the pulp in the tank evenly with a mixer.

- Next, transport the uniform pulp to the pulp supply tank.

- When the pulp in the pulp supply tank reaches a certain consistency, it is sent to the automatic egg tray machine.

- Then, the automatic egg tray machine produces the egg tray to the conveyor belt, which passes through the drying hole to dry the egg tray.

- Finally, we collect and pack the trays.

Advantages of pulp egg tray molding machine

- The automatic egg tray machine has a separate high-pressure spraying pump. The mesh belt drive is frequency-controlled.

- We can adjust both sides of the machine’s guardrail left and right. So, it is suitable for cleaning different sizes of egg trays.

- The machine has the function of automatic temperature control. The alkaline water and hot water tank can be heated by steam or electric heating.

- The drainage of the two water tanks and the overflow port is a unified pipeline discharge standard, which can better keep the cleaning workshop hygienic and clean.

Our company’s services

- One year after-sales service. Within one year of receiving the machine, customers can give us feedback if they have any problems. We will provide all kinds of after-sales services.

- Installation of the automatic egg tray machine. As long as the customer has requested our help to install the machine, we will let the technical personnel go to the local installation of the machine.

- Designing factory drawings. We can provide customers with draft factory drawings if they need them.

Which countries have we exported to?

So far, we have exported automatic egg tray machines to many countries, such as Nigeria, Bolivia, Cameroon, Colombia, Morocco, Sri Lanka, and so on. Every customer is satisfied with the machine. We have received positive feedback from our customers and we will work harder to improve our egg tray machine manufacturing. We will provide better quality products to our customers and bring more convenience.