Egg Tray Manufacturing Plant Paper Pulp Molding Machines

| Model | SL-3*4 |

| Capacity | 2000-2500pcs/h |

| Paper consumption | 200kg/h |

| Water Consumption | 450kg/h |

| Energy used | 58kw/h |

| Worker | 4-5 |

You can now ask our project managers for technical details

The egg tray manufacturing plant with 1000-8000 pieces/hour industrial grade production capacity + 98% raw material recycling rate, which can meet the demand for shock-absorbing protection in the fields of food, medicine, and electronics.

By changing molds, you can convert used cartons and newspapers into a wide variety of trays, such as egg cartons, colored egg trays, apple trays and coffee trays, to meet the diverse needs of the global market.

At the heart of the production line is the egg tray molding machine, supported by pulping, drying, hot pressing and packaging systems to ensure smooth and efficient production.

Our equipment has served customers in countries such as Nigeria, Bolivia, Cameroon, Colombia, Morocco and Sri Lanka. If you are considering starting an egg tray manufacturing business, feel free to contact us for customized solutions!

Raw materials for egg tray production line

The main raw materials for an egg tray manufacturing plant are waste paper (like cardboard, newspapers, books, and magazines) and water. Waste paper should be clean, free of contaminants, and consistent in thickness.

In the pulp-making process, chemicals such as sodium hydroxide, sodium silicate, and aluminum sulfate are added to break down the paper fibers, enhancing the ease of forming egg trays. The chemical usage depends on the type of paper and the required product quality.

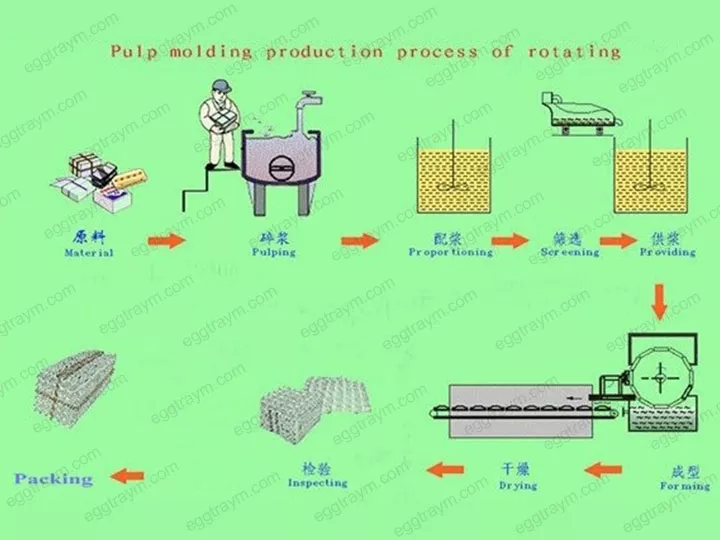

Workflow of egg tray manufacturing plant

The main workflow of an egg tray manufacturing plant includes four key steps: pulp making → pulp molding → drying → packaging.

Equipment involved typically includes paper pulpers, paper tray forming machines, dryers, heat presses, and packaging machines.

Depending on the production line, the drying process may use continuous drying machines, brick kilns, or natural air drying. In semi-automatic setups, drying, hot pressing, and packing are done manually.

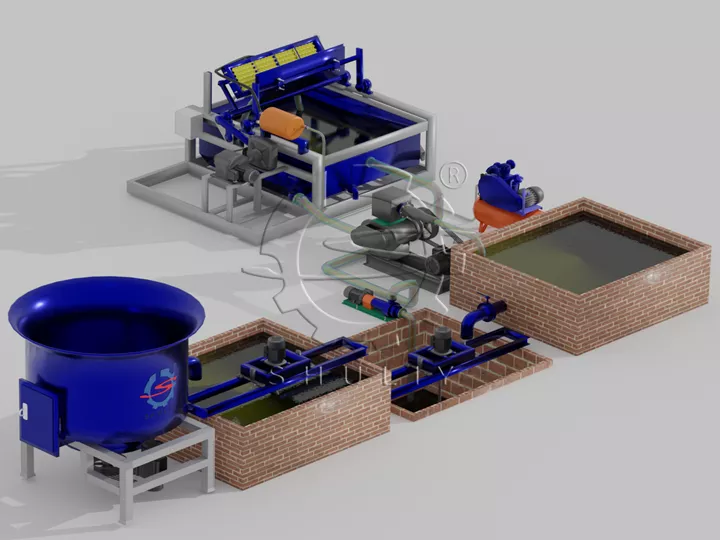

Main equipment of paper tray production line

The equipment used in the egg tray manufacturing plant is capable of managing high volumes of egg tray production while maintaining product quality and consistency. So, what are the key pieces of equipment in the egg tray production line?

Pulping machine

Typically, just one worker is needed to mix waste paper and water in a 1:3 ratio, turning it into a fine pulp. If a color change is desired, colorants can be introduced at this stage.

Egg tray forming machine

Our egg tray machine comes in various models, with an output ranging from 1500 to 8000 pieces per hour, allowing you to select one that fits your requirements. (Read more: Fully Automatic High Capacity Egg Tray Machine>>) Additionally, we offer customized molds, making it easy for you to switch them out whenever needed.

Drying machine

After demolding, the egg tray contains about 30% water, so it needs to be dried and cured. We offer various types of drying machines, including brick kiln drying and continuous drying. Each drying method comes with its own pricing and production efficiency. (Related Post: Egg Tray Dryer Multi-layer Continuous Drying Machine>>)

Heat press machine

The hot press is effective in further shaping the dried egg tray. After undergoing hot press treatment, the egg tray becomes tougher and more defined.

Packaging machine

Egg trays undergo inspection to identify any defects, including cracks, deformation, and uneven surfaces. Any defective trays are discarded, while the remaining ones are counted, stacked, and prepared for sale or use.

Complete paper carton production line parameters

| Model | Capacity | Paper consumption | Water consumption | Energy used | Worker |

| SL-3*1 | 1000-1500pcs/h | 120kg/h | 300kg/h | 32kw/h | 3-4 |

| SL-4*1 | 1500-2000PCS/h | 160kg/h | 380kg/h | 45kw/h | 3-4 |

| SL-3*4 | 2000-2500pcs/h | 200kg/h | 450kg/h | 58kw/h | 4-5 |

| SL-4*4 | 3000-3500pcs/h | 280kg/h | 560kg/h | 78kw/h | 4-5 |

| SL-4*8 | 4000pcs/h | 320kg/h | 600kg/h | 80kw/h | 5-6 |

| SL-5*8 | 5000pcs/h | 400kg/h | 750kg/h | 85kw/h | 3-4 |

| SL-5*12 | 6000pcs/h | 480kg/h | 900kg/h | 90kw/h | 3-4 |

| SL-6*12 | 8000pcs/h | 640kg/h | 1040kg/h | 100kw/h | 3-4 |

Advantages of paper pulp egg tray making line

- Simple equipment assembly, easy to put into use, strong site suitability.

- The fuel system is compatible with multiple energy sources, and only 380V industrial electricity is required for power supply.

- The yield rate of paper trays is stabilized at over 99%, and the manual intervention rate is reduced by 95%.

- Adopting multi-layer continuous drying, the cycle time is shortened to 1-2 hours, and the energy consumption is greatly reduced.

- Vertical layout of multi-layer drying line reduces the space occupied compared with natural drying method.

Why choose our pulp egg tray processing plant?

- Attentive service: quick response, provide sufficient information to help you buy with peace of mind.

- Tailor-made: customize the optimal production line plan according to budget, site and production.

- Durable equipment: built with high quality raw materials, long service life.

- Worry-free after-sales service: enjoy one-year after-sales support, solve your problems in time.

Egg tray machine production line sold to Colombia

A customer from Colombia, who was new to egg tray machines, reached out to us to set up their first egg tray manufacturing plant. To help them understand the features, our salesperson shared detailed pictures and videos.

We then provided specifications for all the available models, allowing the customer to choose the best fit for their needs. After careful consideration and discussion with their partner, they decided to purchase a complete egg tray production line from us.

Understanding the egg tray manufacturing process is essential for selecting the appropriate machine. If you have any questions regarding the egg tray manufacturing plant, please submit your inquiry using the message form on the right, and we will respond within 24 hours.