What is the workflow of the egg tray production line?

Whether it is a semi-automatic or fully automatic egg tray production line, they all have a similar workflow. There is no difference in the finished product, only in the speed of work. In order to let customers understand the workflow of our egg tray machine more clearly, this article will introduce it to customers in detail. If you have any other questions, please do not hesitate to contact us!

What are the machines included in the egg tray production line?

Semi-automatic paper egg tray production line: pulping machine, egg tray forming machine, drying machine.

Fully automatic egg tray production line: paper shredder, egg tray machine, drying machine (brick kiln drying, metal drying machine), hot press, baler, stacker.

The work steps of complete egg tray production line

1. Pulper

No matter whether the production line is semi-automatic or fully automatic, all of them include a paper pulper. A pulper is a machine that is specially used to make raw materials for egg trays. Put the raw materials such as waste paper scraps into the pulp-making machine, add water and other raw materials and break them into pulp. This process is equivalent to recycling those used paper scraps. It is a step to recreate them into egg trays.

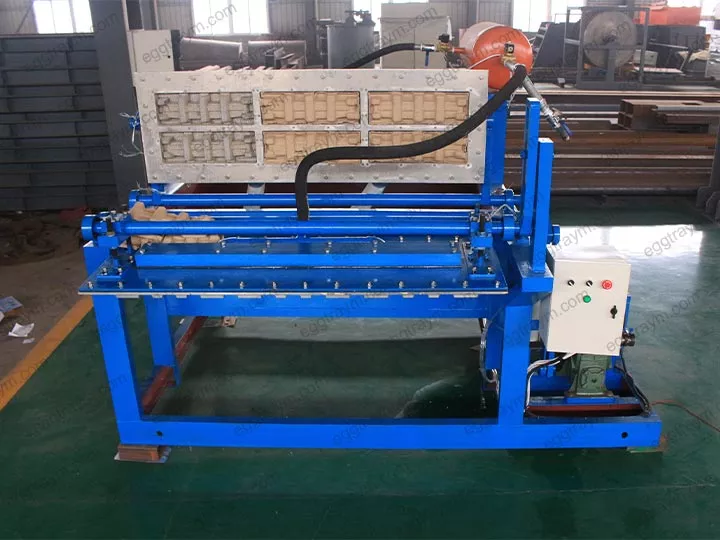

2. Egg tray machine

This machine is the machine for making egg trays. The finished pulp is transported to the egg tray machine through a pipe. Different molds can be installed on the egg tray machine. Different molds can make different styles of egg trays. Customers can also use the same machine to produce industrial packaging such as apple trays and wine trays by changing different molds. After the successful shaping, the egg tray is still wet.

3. Dryer

The wet egg tray needs to be dried by manual drying, brick drying line, or metal dryer. Generally, egg tray production lines with large output are equipped with egg tray dryers. The multi-layer metal egg tray dryer can handle multiple egg trays in one large batch. The metal dryer covers a small area and generates uniform heat, which is welcomed by many customers.

4. Hot press

The hot press is to further plasticize the dried egg tray by heating the mold. After hot pressing, the egg tray is more beautiful and durable.

5. Packing machine

In order to save storage space and facilitate handling and transportation. The workers will put the hot pressed egg tray through the packing machine to press the egg tray tightly. This way, the egg trays will be stacked together. The beaten egg trays are sent to major chicken farms, shopping malls, and supermarkets to realize their value.

This is the workflow of the automatic egg tray production line. Semi-automatic egg tray production lines are usually dried by hand using the sun and wind. Afterward, all the egg trays are handled manually.

We will recommend the right combination of egg tray machine lines according to the customer’s specific situation. Factors to be considered include the customer’s budget, the size of the plant, available fuel, weather, labor input, etc.