Egg Carton Production Line Paper Tray Making Machines

| Model | SL-4*8 |

| Capacity | 4000pcs/h |

| Paper consumption | 320kg/h |

| Water Consumption | 600kg/h |

| Energy used | 80kw/h |

| Worker | 5-6 |

You can now ask our project managers for technical details

The egg carton production line is a complete set of equipment system integrating pulping, molding, drying and packing, designed for the efficient production of pulp-molded egg trays.

Users only need to purchase this complete set of equipment, without the need to purchase additional auxiliary facilities, you can directly start the egg tray production business.

This centralized configuration not only greatly saves selection time and purchasing costs, but also simplifies the operation process and improves production efficiency.

With a capacity of 1,000-8,000pcs/h available for allocation, it is an ideal choice for start-up factories, small-scale processing plants, or expanding production projects.

Finished products of egg carton production line

The egg carton production line can not only be used to produce traditional egg trays, but also to manufacture pulp molding products for various purposes, depending on the changes in molds and demands. It is widely used in many fields such as agriculture, food packaging, and logistics protection:

- Standard 30pcs and 6/10/12pcs retail type egg trays (with or without lid).

- Assorted fruit trays, such as apples, mandarin oranges, etc. Shockproof packaging.

- 2-cup or 4-cup pulp coffee cup holders, eco-friendly alternative to plastic.

- Shoe supports or shoe trays for transportation and styling protection.

- Electronic products cushioning tray, such as headphones, batteries and other shockproof packaging.

- Pharmaceutical trays, safe packaging for fragile products such as medicine bottles, ampoules, etc.

- Support customized molds to produce personalized trays such as light bulb trays, wine bottle trays, cosmetic trays and so on.

What is high-quality pulp?

Making high-quality pulp first requires a high-quality pulp-making machine. A high-quality pulp machine works smoothly and powerfully to effectively process the waste paper raw material. The treated pulp is fine and uniform. In addition, we need to treat the raw material cleanly and remove impurities.

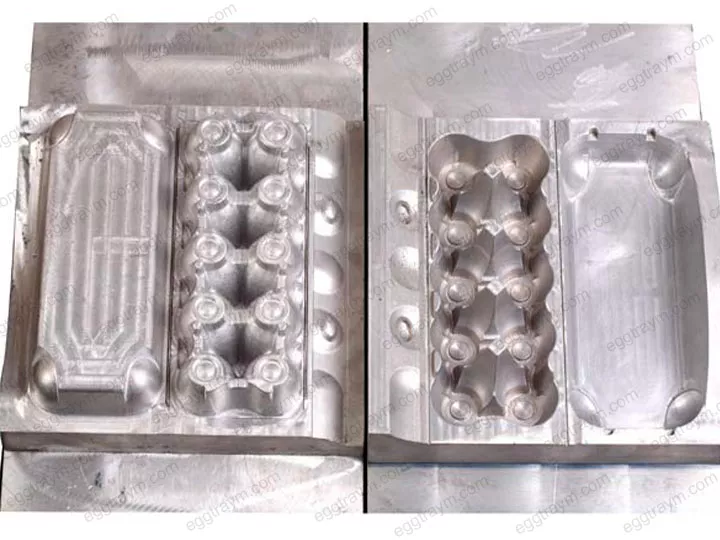

How is the egg tray formed?

Egg tray molding: the polished pulp is transported to the egg tray machine, where the molds on the egg tray machine shape the pulp. After that, the molded egg tray is created. The egg tray is then ready for the next drying process.

Colorful egg tray: making a colorful egg tray is relatively simple. You can put the appropriate pigments into the pulp pool and mix them well.

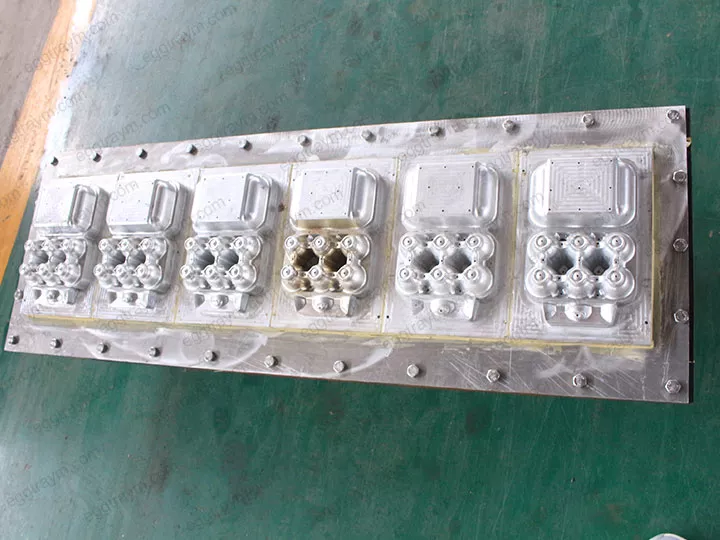

How does egg tray machine produce many forms of egg trays?

Egg tray: the paper pulp egg tray making machine manufactures egg trays mainly through mold shaping. Therefore, if you want to get different forms of egg trays, you only need to change the molds.

Other trays: in addition to egg trays, we have other forms of molds to support the production of different shapes of trays. For example, wine trays, apple trays, pear trays, orange trays, and other kinds of packaging trays.

Types of equipment for drying the egg trays

Generally speaking, there are three kinds of equipment for drying egg trays applied in the egg carton production line.

- Natural drying: suitable for small semi-automatic egg carton production lines, utilizing natural wind and sunshine for drying, with low investment cost, but requiring more labor and space, generally used with drying racks.

- Brick drying line: suitable for medium output egg carton production line, a tunnel drying channel is formed by a brick structure. The hot air circulation makes the egg tray finish drying in a short time, the efficiency is higher than natural drying, and the cost performance is high.

- Metal automatic continuous drying equipment: designed for a large output production line, adopting a multi-layer metal structure, it can dry a large number of egg trays at the same time. The hot air distribution is even, the drying speed is fast, the effect is stable, the automation degree is high, and it saves labor.

How to choose the right paper egg tray production line?

When purchasing an egg carton production line, please combine with your own actual needs, from the following aspects for comprehensive consideration:

- Determine the output demand: how many egg trays do you want to produce per day or per hour? (Key)

- Whether you need drying equipment: whether to match the metal drying line to improve the drying efficiency?

- Define finished product requirements: is there any special need for shape, size, color, etc. of the finished product?

- Budget range: what is the budget of the equipment you plan to invest? (Key)

- Focus: any special requirements such as energy saving, land occupation, automation or maintenance?

Egg tray production line technical parameters

| Model | Capacity | Paper consumption | Water consumption | Energy used | Worker |

| SL-3*1 | 1000-1500pcs/h | 120kg/h | 300kg/h | 32kw/h | 3-4 |

| SL-4*1 | 1500-2000PCS/h | 160kg/h | 380kg/h | 45kw/h | 3-4 |

| SL-3*4 | 2000-2500pcs/h | 200kg/h | 450kg/h | 58kw/h | 4-5 |

| SL-4*4 | 3000-3500pcs/h | 280kg/h | 560kg/h | 78kw/h | 4-5 |

| SL-4*8 | 4000pcs/h | 320kg/h | 600kg/h | 80kw/h | 5-6 |

| SL-5*8 | 5000pcs/h | 400kg/h | 750kg/h | 85kw/h | 3-4 |

| SL-6*8 | 6000pcs/h | 480kg/h | 900kg/h | 90kw/h | 3-4 |

| SL-8*8 | 8000pcs/h | 640kg/h | 1040kg/h | 100kw/h | 3-4 |

Our factory has many years of experience in producing and exporting egg tray machines and has shipped them to Peru, Bolivia, Saudi Arabia, the United Arab Emirates, Kenya, Indonesia, Cameroon, Zimbabwe, Uganda, and many other countries.

We can customize the paper tray forming machine according to your business size and finished product needs. Feel free to contact us for more information and we will make the right recommendation for you.