Fully Automatic High Capacity Egg Tray Machine

| Model | SL-3*4 |

| Output | 2000-2500pcs/h |

| Paper consumption | 200kg/h |

| Water Consumption | 450kg/h |

| Energy used | 58kw/h |

| Work number | 4-5 |

You can now ask our project managers for technical details

The fully automatic egg tray machine is based on the core of waste paper recycling technology, realizing a single machine with an industrial-grade capacity of up to 7,000 pieces/hour. It can support the production of 6/12/24/30 pieces and 12 types of shaped trays, such as ostrich eggs and quail eggs.

The machine is available in single, four, eight and twelve-sided configurations to meet the diverse needs of family farms to 10,000-ton processing plants.

Its mold casting technology can replicate the samples provided by customers 1:1 (error ± 0.1mm), and support grams (15-80g), thickness (0.8-3.5mm), and anti-vibration structure of the depth of customization. The compressive strength of the egg tray can be increased to more than 35kg.

Manufacturers adopting this machine can realize the reduction of raw material cost (98% utilization rate of waste paper) and energy-saving multi-layer drying line heat recovery technology.

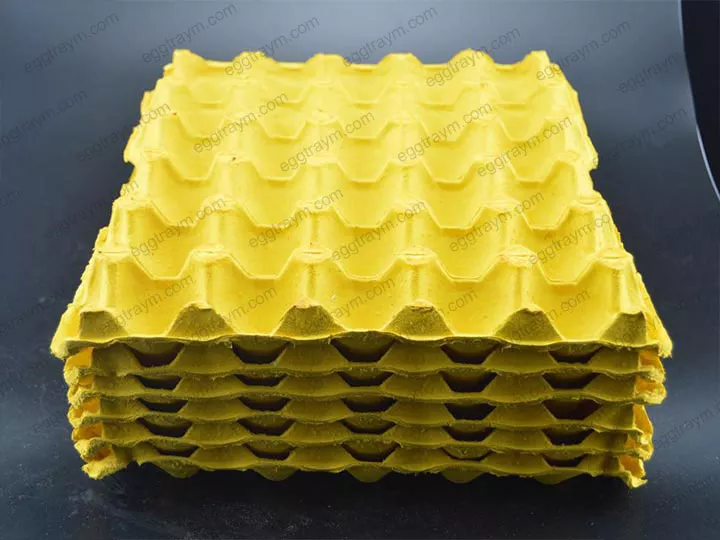

Color, weight, and shape can be freely customized, and exclusive molds can be made according to customer samples and dimensions.

Immediately start the automation upgrade, experience the ultimate stability and flexibility of the egg tray production solutions, to learn more about the details, please continue to read below.

Raw materials and application of rotary egg tray machine

A diverse range of materials can be used to produce egg trays. This includes waste paper from printing companies, pre-made plant fiber pulp, and paper pulp; discarded books and magazines from publishers; shredded paper from businesses, institutions, and government offices; as well as old newspapers, magazines, second-hand books at home, express cartons, and packing boxes.

Scope of use: the tray can be used to pack eggs, fresh fruits, electrical appliances, fragile products, agricultural appliances, food packaging, medical appliances, etc.

What are the benefits of pulp egg trays?

Pulp egg trays have clear advantages over plastic ones in terms of cost, environmental impact, and material characteristics.

- Waste paper is readily available and inexpensive to purchase, making it a low-cost investment for recycling.

- It is considered a green packaging option, as it does not contribute to air or water pollution.

- The material has a soft texture, providing excellent protection for fragile eggs during transport.

- It also offers good thermal insulation and is resistant to static, water, moisture, shock, and corrosion.

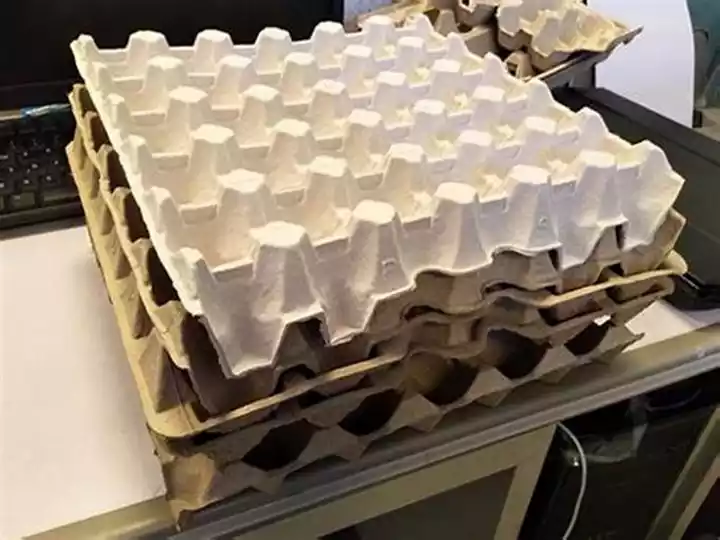

- Its lightweight and stackable nature helps save on storage and transportation costs.

- The material exhibits strong resistance to bending and tearing, along with good plasticity and cushioning properties.

Automatic egg tray machine technical parameters

If you’re just starting or have limited capital, consider beginning with small-scale production. However, if you have sufficient funds and experience and are looking to expand your operations, medium or large-scale production may be the right choice for you. We offer suitable egg tray machines for each level of manufacturing. Contact us for the most suitable program!

| Model | SL-3X1 | SL-3X4 | SL-6X8 |

| Capacity | 1000pcs/h | 2500pcs/h | 7000pcs/h |

| Voltage | 380V,50HZ | 380V,50HZ | 380V,50HZ |

| Power | 38kw | 55kw | 120kw |

| Weight | 2500kg | 4000kg | 10000kg |

| Overall dimension | 2600*2200*1900mm | 2900*1800*1800mm | 3200*2300*2500mm |

| Paper consumption | 80kg/h | 200kg/h | 480kg/h |

| Water consumption | 160kg/h | 400kg/h | 960kg/h |

| Drying method | Dry naturally or use a dryer | Brick kiln drying or multi-layer dryer | Brick kiln drying or multi-layer dryer |

For more information about small egg tray machines, please click Semi-Automatic 1500PC/H Egg Tray Making Machine For Sale.

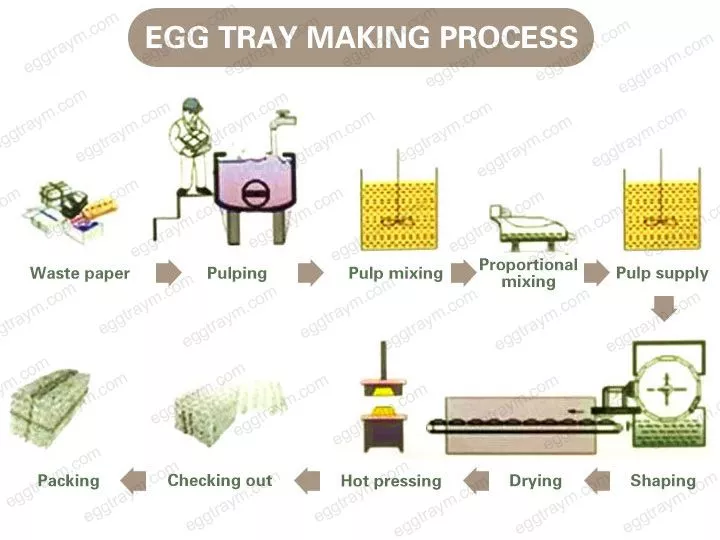

How does paper egg tray making machine work?

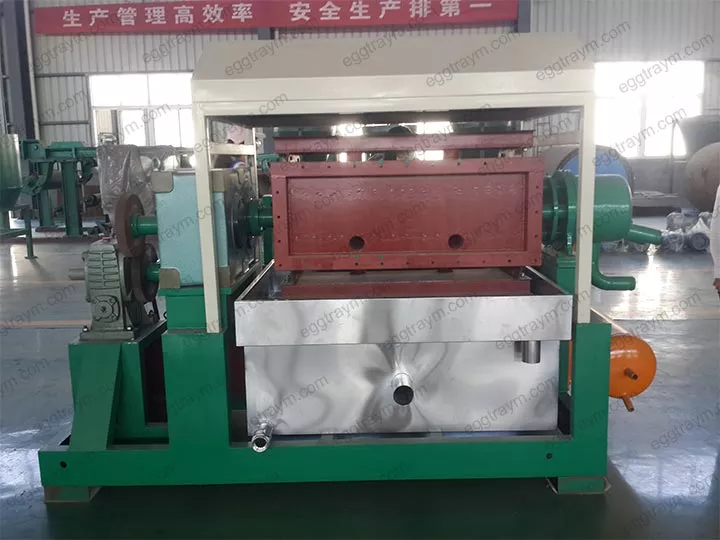

The egg tray production line mainly includes a pulp-making machine, vacuum pump system, automatic egg tray machine forming machine, egg tray drying machine, hot pressing machine, egg tray packing machine, etc.

- Start by adding waste paper to the pulp shredder along with some water. Once shredded, transfer the pulp to the storage tank and mix it thoroughly using a mixer.

- Next, move the uniform pulp to the supply tank. When the pulp in the supply tank reaches the desired consistency, it is directed to the automatic egg tray machine.

- The automatic egg tray machine then creates the egg trays, which are sent to the conveyor belt that leads through the drying area to dry the trays. Finally, we gather and package the trays.

Pulp egg tray molding machine advantages

- The automatic egg tray machine features a dedicated high-pressure spraying pump, and its mesh belt drive operates on a frequency control system.

- You can adjust the guardrails on both sides of the machine to accommodate various sizes of egg trays, making it versatile for cleaning.

- This machine is equipped with automatic temperature control. The alkaline water and hot water tanks can be heated using either steam or electric heating methods.

- The drainage system for the two water tanks and the overflow port is designed with a unified pipeline discharge standard, ensuring that the cleaning workshop remains hygienic and tidy.

Our company’s services

- Regarding factory drawings, we can create draft factory layouts for customers upon request.

- We prioritize timely production, delivery, and safe transportation to the correct destination.

- For the installation of the automatic egg tray machine, if a customer requests assistance, our technical team will travel to their location to help with the installation.

- We offer a one-year after-sales service. Customers can reach out to us within a year of receiving the machine if they encounter any issues, and we will provide a range of after-sales support.

- Our automatic egg tray machine holds CE and ISO9001 certifications, guaranteeing a zero defect rate for the equipment.

- Our large-scale production workshop benefits from low raw material costs, allowing us to offer factory prices on our equipment.

Successful cases

We have been manufacturing automatic egg tray machines for over 20 years. Our machines have been exported to numerous countries, including the UAE, Pakistan, Saudi Arabia, Egypt, India, Algeria, Australia, Somalia, Nigeria, Ghana, Bolivia, Senegal, Cameroon, Colombia, Morocco, Sri Lanka, and so on.

We have received great feedback from our customers, and we are committed to enhancing our automatic egg tray machine manufacturing. Our goal is to deliver higher quality products and offer more convenience to our customers.

Contact us at any time

Thank you for your interest in our company and automatic egg tray machine, please leave your detailed information, and we will reply to you within 24 hours. To better assist you with a tailored solution, please take into account several factors and clearly outline your requirements regarding the following:

- What are your raw materials?

- What is your expected end product?

- What is your production scale?

- What is the planned layout of your production plant?

- What is the budget for purchasing machines for your project?

By providing us with detailed information, we can gain a better understanding of your needs. This will also help us analyze and address any technical issues you may encounter during the production process, ultimately maximizing your benefits. We look forward to collaborating with you further!