How To Make Pulp In The Egg Tray Making Plant

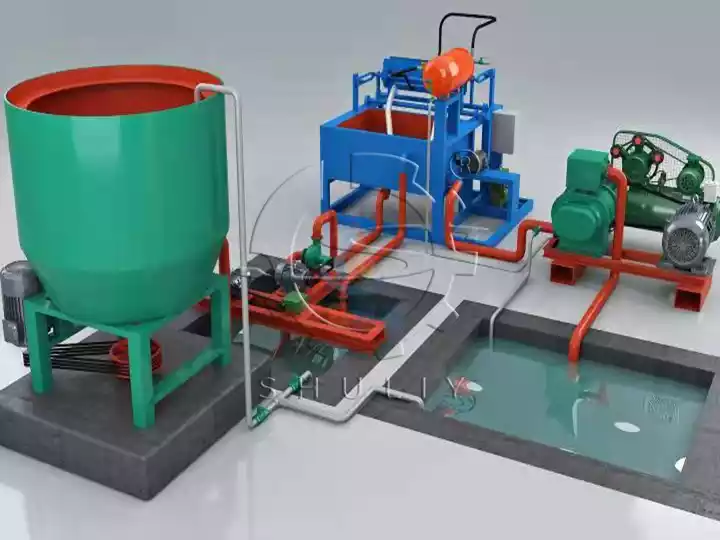

In the egg tray production line, the efficient operation of the paper pulp machine is crucial to the overall efficiency, and its main role is to convert waste paper into pulp to provide the basic raw material for subsequent egg tray molding.

Raw Material For Pulper

Egg tray production is mainly a waste paper recycling process. So the source of pulp is waste paper sheets, paper packing boxes, and so on. Larger raw materials are not suitable for direct access to the pulp machine, so they need to be operated with the help of a shredder first.

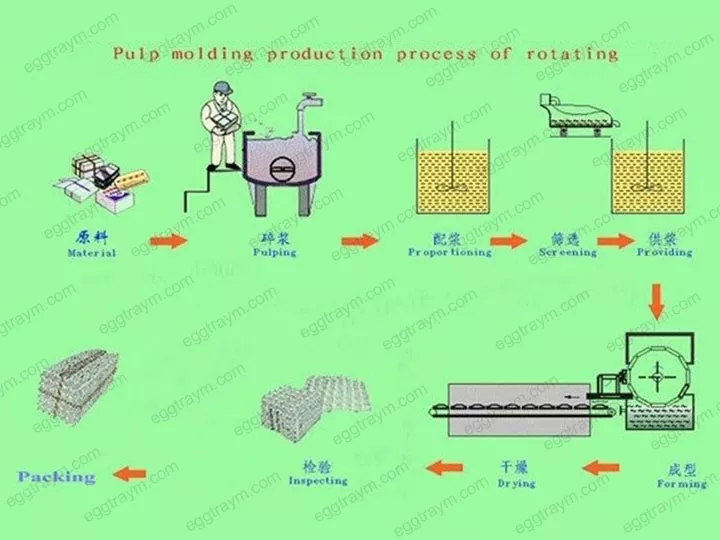

How To Make Paper Pulp

- Waste Paper Soaking: Firstly, the collected waste paper is fed into the soaking tank for soaking. This process helps to soften the paper and make it easier to decompose.

- Pulp Pulverizing: After soaking, the waste paper is meticulously chipped and broken up to form a fine, fibrous substance. This is a key step in the preparation of pulp, ensuring that the waste paper is well dispersed.

- Forming Pulp: After soaking and pulverizing, the waste paper is formed into pulp, which contains fine fibers, moisture, and other paper components. This step is designed to provide a homogeneous raw material for the subsequent molding process.

The paper pulp making process uses waste paper materials at a lower cost and enables the recycling of resources, effectively reducing the pressure on the exploitation of forest resources. In addition, this process ensures the uniform thickness and sturdiness of the egg tray, which improves the overall quality of the product.