How to Make Egg Tray from Waste Paper?

Through modern egg tray machines, waste paper is transformed into high-value-added packaging products. This approach meets the characteristics of environmental friendliness, low cost, and high demand, making it the preferred investment project for entrepreneurs and processing plants.

So, how exactly does waste paper become egg trays? This article will take you through the comprehensive paper tray production process and its commercial advantages.

Why is waste paper an ideal egg tray material?

The raw materials required for paper tray production are remarkably simple: just waste paper + water. Common household items like old newspapers, used books, cardboard boxes, and discarded egg trays can all serve as production materials. This ensures low raw material acquisition costs, abundant sources, and strong sustainability.

Compared to traditional plastic trays, pulp egg cartons are biodegradable, recyclable, and environmentally friendly. They align with global plastic ban trends and represent the future mainstay of the packaging industry.

Four core steps from waste paper to egg cartons

Modern paper tray production lines primarily consist of four stages: pulping, forming, drying, and packaging. Each step is supported by specialized equipment, enabling an efficient, continuous, and eco-friendly production model.

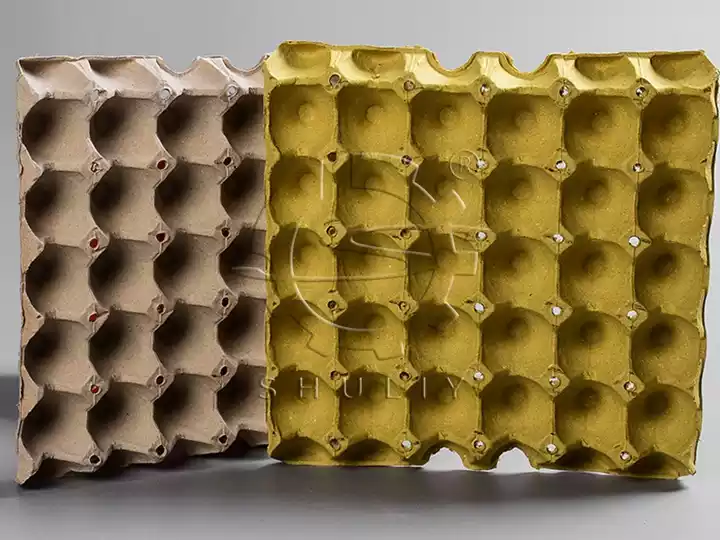

By switching different molds, the line can produce:

- 30-cell egg cartons(mainstream model)

- 24-cell egg cartons

- 6/12-egg cartons

- Medical trays

- Fruit trays

- Electrical cushioning packaging

This multi-functional capability significantly enhances investment value.

Customizable drying options based on client needs:

- Natural air-drying (suitable for low output and stable climates)

- Automatic metal drying lines (daily output ranging from 10,000 to 200,000 trays)

- Multi-layer energy-efficient drying chambers (fuel options: natural gas, diesel, wood, biomass)

3 Advantages of investing in egg tray machinery

Low cost, high profit: raw material waste paper costs are virtually zero or extremely low. Both entrepreneurs and large factories can achieve rapid return on investment.

- Small-scale equipment produces 1,000–1,500 egg cartons per hour.

- Medium-to-large production lines achieve a daily output of 50,000–200,000 egg cartons.

Global plastic bans and the food packaging industry’s transformation are propelling molded pulp products into mainstream adoption. Egg tray machines produce biodegradable products aligned with environmental policies, receiving dual support from government agencies and the market.

Mold replacement enables the production of: electronics packaging trays, fruit trays, medical device trays, seedling pots, and takeout containers. A single production line covers multi-industry demands, reducing investment risk.

Note:

- Excessive sand or impurities compromise paper tray appearance and strength. Ensure thorough pre-treatment of waste paper.

- High-precision aluminum or copper molds guarantee smooth, consistent surfaces, extend service life, and enable custom logo imprinting.

For inquiries, feel free to contact us anytime!