Egg Box Making Machine Sent to Saudi Poultry Company

Recently, a Saudi Arabian company specializing in producing free-range eggs decided on an egg box making machine in the face of the challenges of imported paper egg trays that are easily deformed in high-temperature environments and costly.

The company had long relied on imported egg trays, but the high cost of packaging (60% of the overall packaging cost) and the stability of the trays in extreme heat conditions were severely limiting its competitiveness in the market.

Customer needs analysis

Given the hot climatic conditions in Saudi Arabia, traditional paper egg trays are highly susceptible to damage during transportation and storage, which not only increases wastage but also affects the quality performance of eggs.

In addition, high import costs made it urgent for the business to find a solution that was both economical and practical. As a result, the company decided to explore the localized production route with a view to reducing costs and improving the stability of the packaging material.

Selection of egg box making machine

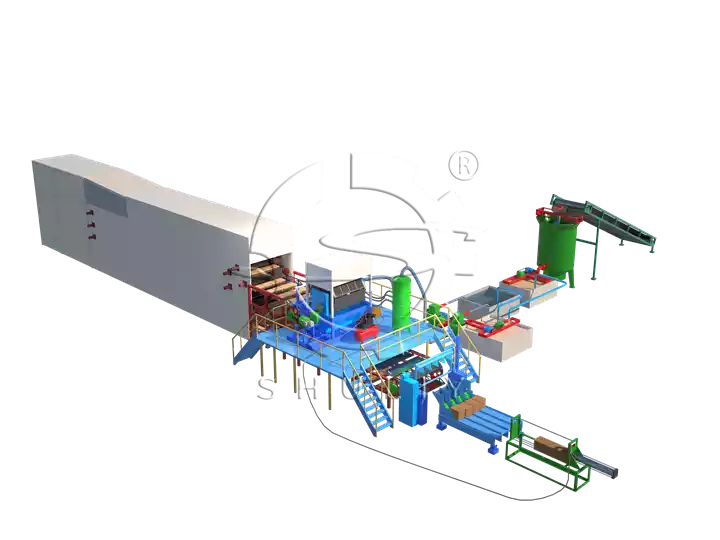

After careful market research and technical evaluation, the enterprise finally chose a small modular design egg tray forming machine with a design capacity of 1,500 pieces/hour, which is sufficient to meet its daily packaging demand of 30,000 eggs.

The highlight of this egg box making machine is its servo control system, which can withstand high temperatures of up to 50°C. This system is perfectly suited to the high-temperature environment in Saudi Arabia and ensures the stability of the egg tray in production and subsequent use.

For more details about the above egg box making machine, please click Semi-Automatic 1500PC/H Egg Tray Making Machine For Sale.

Why choose our egg tray machine?

- Small modular design for easy operation and maintenance, improving overall production efficiency and flexibility.

- Localized production significantly reduces the purchase cost of egg trays and solves the problem of expensive imported egg trays.

- High-temperature adaptable design ensures the stability of egg trays in Saudi Arabia’s extreme climate and reduces wastage during transportation and storage.

- The use of recycled pulp is in line with the company’s commitment to sustainable development and enhances the brand image.

On the day of shipment, the technicians carried out the final inspection and packaging of the machines to be shipped to ensure that they would not be damaged during the long-distance transportation, and finally they were successfully shipped to Saudi Arabia.