Enhancing Production Automation: Saudi Arabia SL-6*12 Egg Tray Processing Plant

Customers in Saudi Arabia have long relied on semi-automatic egg tray machines, which require frequent manual operations. This resulted in low productivity, high labor intensity, and increased operating costs. With growing market demand for paper-based packaging products and rising labor costs, the customer urgently needed to upgrade to a more automated and efficient egg tray processing plant system.

Change objectives and solution actions

The customer’s primary goal was to increase production automation by more than 50 percent while ensuring smooth production operations.

The goal was to meet the needs of a growing regional market with smarter and more sustainable production methods, reducing reliance on labor and lowering long-term operating costs.

Solution: SL-6*12 with metal drying system

Understanding the customer’s needs: Shuliy’s technical and sales teams worked closely with the Saudi customer to identify the pain points in their current operations and define their production goals and automation expectations.

Egg tray processing plant project details

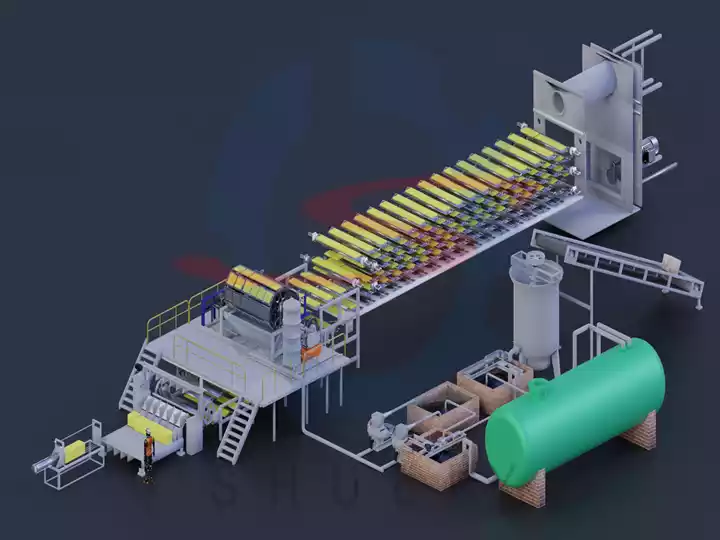

For this reason, We proposed a customized solution: the SL-6*12 Egg Tray Line, integrating a fully automated metal drying system and an egg tray collection and stacking unit.

This integrated system is designed to significantly reduce manual handling, improve product consistency and optimize energy efficiency. It is configured as follows:

- Throughput: 6,000-7,000 pcs/hour

- Number of molds: 48

- Raw material: waste paper

- End product: paper egg tray

- Additional equipment: all-metal drying system, automatic stacking and collecting device

- Installation: on-site technical supervision by Shuliy engineers

Building trust with global case studies

To build customer confidence, we share case studies of successful applications of automated egg tray systems in countries with similar climates and operating environments. These real-life cases demonstrate Shuliy’s extensive experience and strong after-sales capabilities, thereby enhancing customer trust.

Achieved results

The SL-6*12 egg tray processing plant has now been successfully installed and commissioned at the customer’s plant in Saudi Arabia.

The system, which is expected to produce more than 50 million egg trays per year, efficiently converts waste paper into molded trays. These trays are quickly dried by a continuous metal drying system and then stacked and packaged in a seamless, automated process. (Read more: Egg Tray Manufacturing Plant Paper Pulp Molding Machines)

The customer currently operates an efficient and sustainable egg tray production line that meets environmental goals and local market demand.