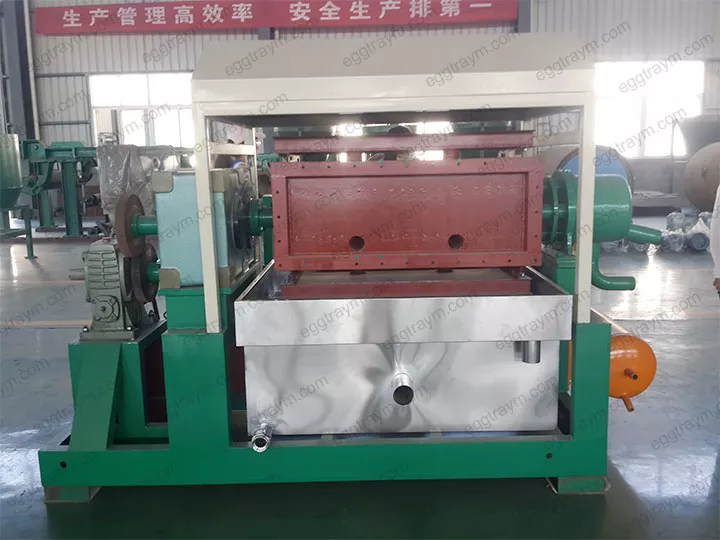

Egg Box Machine Paper Carton Molding Equipment

| Model | SL-4*8 |

| Capacity | 4000pcs/h |

| Paper consumption | 400kg/h |

| Water Consumption | 600kg/h |

| Energy used | 80kw/h |

| Worker | 5-6 |

You can now ask our project managers for technical details

The egg box machine is a machine that processes waste paper pulp into shapes such as egg trays. Through mold forming and drying processes, it realizes the reuse of waste paper and is widely used in the packaging industry. There are many models of egg carton making machines we make, that can meet the different needs of customers for output. Welcome to contact us for machine customization.

Brief introduction of the egg box machine

Our egg box machine can make egg cartons of different specifications. And they differ in the number of eggs they hold. For example, there are 4-packing, 6-packing, 8-packing, 12-packing, 24-packing, etc. We can also customize egg boxes with special shapes according to the specific needs of customers.

Since the output of large-scale machines is also large, we recommend customers form an egg tray production line with other machines. This can greatly improve efficiency. The egg box-making machine with a small output can be used as a stand-alone machine.

Raw materials for making egg boxes

The raw materials of egg boxes are various waste papers, such as newspapers, books, magazines, office paper, kraft paper, A4 paper, cardboard, etc.

Usage of egg boxes

As the name suggests, egg boxes are used to hold eggs. The use of egg boxes to pack eggs can protect the eggs to the greatest extent and reduce bumps. At the same time, packaged eggs are more conducive to people’s counting. Moreover, it is also conducive to the stacking of eggs, which can reduce the floor area for storing eggs.

Paper egg tray design

Our egg carton machine can make egg cartons that are often used in the market. At the same time, we can also make uniquely designed egg boxes. Customers need to provide us with detailed information about the egg boxes they need. And we will customize the egg box molds according to the information.

Composition of the egg carton production line

In general, high-yield egg box machines will be equipped with other machines to form a production line. The equipped machines include a pulper, egg box machine, dryer, heat press, packing machine, etc. The egg box machine production line can efficiently make egg boxes. And the finished product is more compact and beautiful.

What factors do you need to consider when choosing an egg box molding machine?

- How many cartons do you need every day?

- How much land area do you plan to use to build the factory?

- What is the local voltage?

- We have three different drying equipment, which type of dryer do you need?

These questions are just a few of many questions, and other details need to be confirmed with you. If you are interested in our products, please contact us immediately. We will provide you with a professional reply.

Egg carton making machine sold to Cameroon

Our customers from Cameroon had a previous farm and wanted to switch to making egg cartons. After we received the customer’s message, we immediately provided the customer with pictures and videos of the egg box machine.

Since it is the first time for the customer to start the egg tray machine business, we recommend a small model egg tray machine to the customer. Then the parameters of the egg box machine were provided to the customer. The customer decided to buy this small model SL-3*1 egg box machine after consideration.

Business cost of an egg tray machine production line

Due to the different configurations of the production line, the cost of the paper egg tray machine production line is also different.

- Regarding drying equipment, we have brick drying lines and metal drying lines. They differ in construction and equipment costs. And we will recommend the right drying equipment for your specific situation.

- Other equipment. In addition to drying equipment, the egg tray production line also has other equipment, such as egg carton heat presses, and egg carton packaging machines, including egg carton stackers. Although the purchase of these devices will increase the cost, it can greatly improve efficiency.

Shuliy’s egg tray making machine

- Our gearbox is imported from Taiwan, which is more energy-saving and runs smoothly.

- The drying system adopts a single-layer energy-saving and environment-friendly drying line. This kind of egg carton machine production line is more energy-saving, the steel structure is single-layer dried, and the installation is convenient, practical, and beautiful.

- During the whole process of using the machine, no wastewater discharge can be recycled.

- The main frame is made of thickened 20# channel steel, and the transmission shaft is made of a sliding shaft to ensure stability.