Semi-Automatic 1500PC/H Egg Tray Making Machine For Sale

| Model | SL-4*1 |

| Output | 1500-2000PCS/h |

| Paper consumption | 160kg/h |

| Water consumption | 380kg/h |

| Energy used | 45kw/h |

| Worker number | 3-4 |

You can now ask our project managers for technical details

The pulp egg tray manufacturing machine is an efficient and environmentally friendly equipment for producing pulp molding products such as egg trays, egg cartons, fruit trays, coffee cup trays, and so on.

Our 1500pc/h egg tray making machine requires only 1 to 3 people to complete the operation and daily maintenance, especially suitable for small enterprises, family workshops, and entrepreneurial projects.

The machine can utilize waste paper such as books, magazines, A4 paper, waste paper trays, cardboard, etc., as raw materials, and adopt a 3:1 water-paper ratio for mixing and pulping.

The equipment has a compact structure, easy to change molds, and is flexible to deal with the production needs of different pallet products.

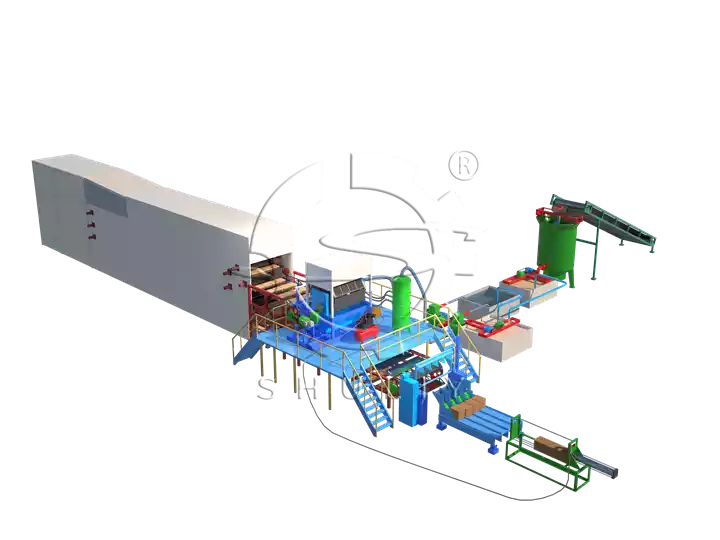

Typically, the 1500pc/h egg tray making machine with a smaller output operates semi-automatically. Our semi-automatic egg tray production line generally consists of pulp machines and forming machines, while the drying and packing processes require manual handling.

Finished products from paper tray machine

The distinctive feature of the paper pulp forming machine is its versatility and variety. By swapping out different molds, it can effortlessly create finished products in various shapes and types, offering users significant production flexibility and options.

What machines can work with small egg tray machine?

The 1500pc/h egg tray making machine can be used in conjunction with an egg tray pulper, a manual drying machine, a packing machine, and more.

You can choose the drying machine, hot press, and packing machine to form a fully automatic production line. (More info: Egg Tray Manufacturing Plant Paper Pulp Molding Machines)

The egg tray machines from our factory have a capacity of 1000 to 6000pc/h. Large-capacity egg tray making machines are usually fully automatic production lines, which can greatly improve work efficiency. (Related post: Fully Automatic High Capacity Egg Tray Machine)

Parameters of 1500pc/h egg tray making machine

| Model | Output | Paper consumption | Water consumption | Energy used | Worker number |

| SL-4*1 | 1500-2000PCS/h | 160kg/h | 380kg/h | 45kw/h | 3-4 |

How does the egg tray molding machine work?

- Raw material pulping: waste paper and water are put into the hydraulic pulper at the ratio of 3:1 and stirred to make uniform pulp.

- Pulp blending: the pulp goes through vibration screening and concentration adjustment, and enters the molding system for spare parts.

- Vacuum adsorption molding: the pulp is adsorbed to the surface of the mold by a vacuum pump to form the desired egg tray shape.

- Remove from mold: after molding, the egg tray is removed from the mold by pneumatic or manual means and transferred to the drying section.

- Drying: the wet egg tray is dried through the hot air drying system to ensure its solid structure and neat shape.

- Finished product collection: the dried egg tray can be directly collected, packed and entered into the sales or use process.

Advantages of the small paper egg tray machine

- Low investment cost: compared with the fully automatic production line, this 1500pc/h egg tray making machine does not need dryer, hot press and packaging machine, the overall cost is lower, suitable for startups.

- Better efficiency than manual equipment: semi-automatic working mode, output and efficiency are much higher than manual egg tray machine, saving labor time.

- Suitable for small and medium-sized investors: 1500pcs/hour capacity meets the daily medium demand, suitable for rural entrepreneurship or home-based production.

- Strong expandability: the equipment structure is modularized, which makes it easy to upgrade to fully automatic production line flexibly according to the business development at a later stage.

- Simple operation and easy maintenance: only 1-3 people are needed to complete the operation and daily maintenance, low labor intensity and small management cost.

How to choose a suitable egg tray molding machine?

There are different types of 1500pc/h egg tray making machines in the market. Customers can choose the suitable egg tray forming machine for them according to the following points:

How many egg trays do you need to produce per hour?

Customers can select the egg tray molding machine based on their production capacity requirements. The output will dictate which model of the egg tray machine is suitable and the dimensions of the egg trays the customer intends to produce.

What is your budget?

Customers should purchase the egg tray manufacturing machine based on their specific circumstances. Besides the device’s price, it’s important to take into account other factors like labor costs, construction expenses, raw material costs, and maintenance fees.

Where to buy the paper egg tray making machine from?

Given the transportation costs, many customers might prefer to purchase the machine locally. Nevertheless, our egg tray machine has received positive feedback from numerous international clients. As a manufacturer, we offer high-quality egg tray machines at competitive prices, along with excellent customer service. Additionally, we provide installation services for the machine as well.

Egg crate making machine sold to Venezuela

Last month, a customer from Venezuela bought an egg tray making machine from us. He intended to use the machine for his purposes, as he owned a chicken farm and wanted to produce his egg trays for packaging his eggs for sale.

During the purchase of the 1500pc/h egg tray making machine, we maintained active communication with the customer, addressing all of their concerns. Providing good communication and service helps ensure that the customer feels confident in their decision to buy our egg tray forming machine!

Famous paper tray making machine manufacturer

Shuliy Machinery has been in operation for over ten years, boasting advanced technology and extensive export experience in the production of egg tray making machines. Our dedicated professional R&D team, along with our manufacturing and supervision staff, is committed to delivering high-quality egg tray manufacturing equipment to our customers!

We have successfully exported to numerous countries, such as Bolivia, Cameroon, Ghana, Venezuela, Kenya, Mozambique, Saudi Arabia, and more. In addition, we have our factory to provide you with factory direct prices. Shuliy Machinery invites you to reach out for inquiries at any time!