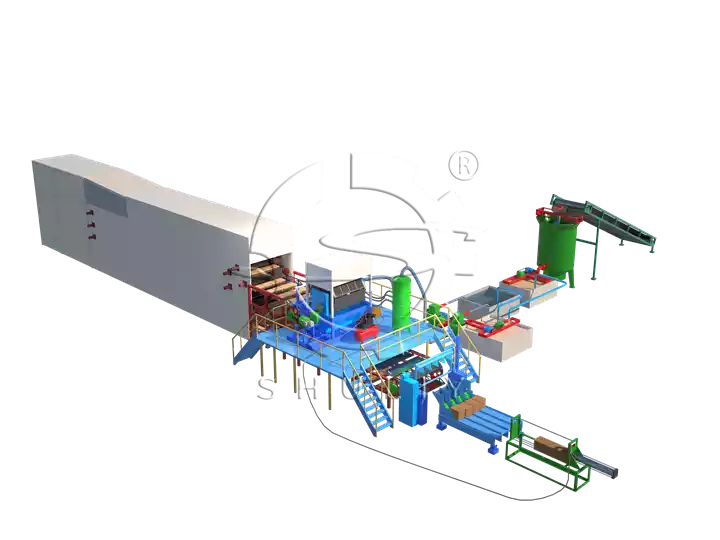

Drying Room Shipped to Cameroon for Egg Tray Production Process Upgrade

We have completed the manufacturing of one drying room and successfully shipped it to Cameroon. The customer had previously purchased an egg tray molding machine from our company in the first half of the year. This purchase of the drying machine aims to complete the full production process of egg trays, thereby enhancing product quality and production efficiency.

Customer background and procurement requirements

The customer primarily engages in the production of egg trays and related eco-friendly packaging products. After purchasing our egg tray machine in the first half of the year, the customer expressed high satisfaction with the equipment’s stability and product quality.

However, in the drying stage following egg tray molding, the customer still relied on traditional air-drying methods, which suffered from issues such as lengthy processing times and uneven drying. Therefore, the customer decided to introduce our drying room to achieve full automation and efficiency in the egg tray production process.

Features and advantages of the drying room

- The box-type dryer is equipped with an intelligent temperature and humidity control system, allowing for flexible adjustment of temperature and humidity according to the drying requirements of different egg tray materials, achieving uniform and efficient drying.

- The equipment has a compact structure and is easy to operate, featuring a circulation fan system to accelerate drying speed while ensuring the egg trays remain undistorted.

- Compared to traditional air-drying methods, this dryer significantly reduces drying cycles, increases production capacity, and reduces reliance on manual labor.

Complete egg tray production line support

By integrating with the customer’s existing egg tray molding machine, the introduction of the drying room enables a fully automated production process from molding to drying. You can also learn more about egg tray drying equipment through: Egg Tray Dryer Multi-layer Continuous Drying Machine.

Customers can not only consistently produce high-quality egg trays but also significantly improve production efficiency, meeting the rapidly growing demand for eco-friendly packaging in Cameroon local market.

We will continue to provide technical guidance and after-sales service to ensure the long-term stable operation of the equipment.