What Are the Pulp Molding Products?

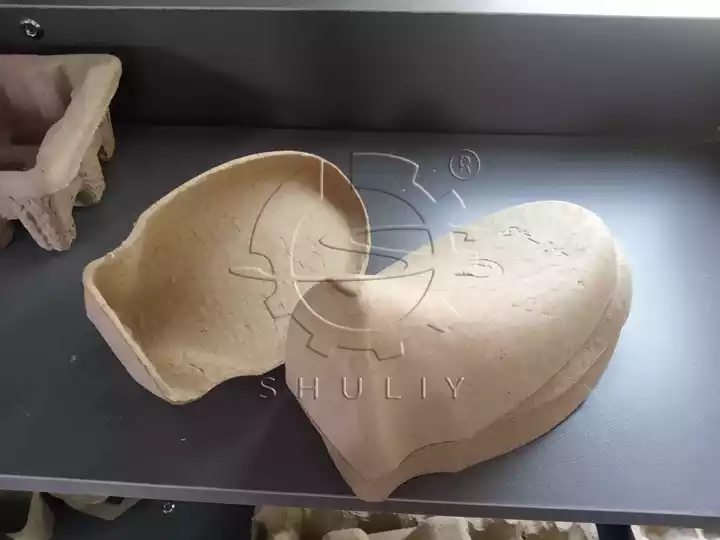

The pulp molding products offer eco-friendly packaging solutions crafted from recycled pulp. Utilizing pulp paper tray machines, these products are formed on custom molds to cater to diverse industrial and consumer requirements. Ranging from egg trays to electronics packaging, these items are transforming sustainable manufacturing.

Types of pulp molding products

Pulp molding technology enables the production of a wide range of versatile, biodegradable products. These items serve as alternatives to single-use plastics, offering both durability and compostability, and include:

- Food and agriculture: egg trays (24/30 count), fruit trays (for apples and pears), wine bottle covers, and nursery pots.

- Electronics: protective trays designed for smartphones, laptops, and appliances.

- Industrial: shoe racks, car wheel spacers, and packaging for machinery.

- Retail: cup holders, cosmetic packaging, and bottle holders.

Why choose pulp molding technology?

Sustainability-driven production

Pulp Molding utilizes recycled paper, such as newspapers and cardboard boxes, as its primary raw material, helping to reduce waste in landfills. This process requires very little water and energy, aligning with the principles of a circular economy.

Cost-effective

This efficient workflow can automate production, leading to high yields and reduced labor costs.

- Pulping: Waste paper is combined with water to create pulp.

- Forming: Vacuum suction is used to shape the pulp into molds for accurate designs.

- Drying: Energy-efficient systems, such as hot press, solar, or natural drying, help minimize moisture.

Customizable and protective

Molds can be tailored to accommodate specific product dimensions, providing secure and shock-absorbing packaging. The porous nature of pulp also allows for ventilation, making it suitable for perishable items like eggs and fresh produce.

Benefit from paper tray machinery for your industry

- Agriculture: seedling trays, crop packaging solutions.

- Food service: single-use tableware, takeout containers.

- Logistics: tailored protective packaging for delicate items.

- E-commerce: lightweight, branded shipping options.

With the worldwide ban on single-use plastics, pulp molded products are set to take over the packaging market. Investing in pulp molding machines enables scalable production and offers a fast return on investment. Don’t hesitate to collaborate with us to transform waste into valuable resources!