Usine de fabrication de plateaux à œufs Machines de moulage de pâte à papier

| Modèle | SL-3*4 |

| Capacité | 2000-2500 pièces/heure |

| Consommation de papier | 200kg/h |

| Consommation d'eau | 450kg/h |

| Énergie utilisée | 58 kW/h |

| Ouvrier | 4-5 |

Vous pouvez désormais demander des détails techniques à nos chefs de projets

L'usine de fabrication de plateaux à œufs avec une capacité de production industrielle de 1000 à 8000 pièces/heure + un taux de recyclage des matières premières de 98 %, qui peut répondre à la demande de protection anti-choc dans les domaines de l'alimentation, de la médecine et de l'électronique.

En changeant de moules, vous pouvez transformer des cartons usagés et des journaux en une grande variété de plateaux, tels que des cartons à œufs, des plateaux à œufs colorés, des plateaux à pommes et des plateaux à café, pour répondre aux besoins diversifiés du marché mondial.

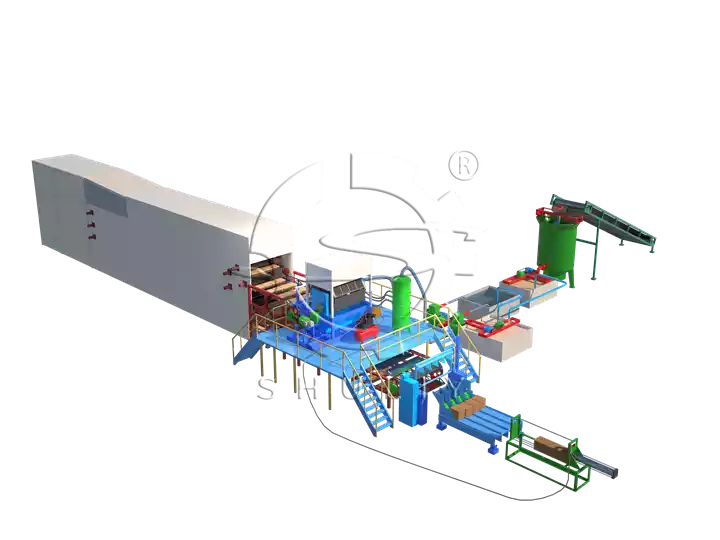

Au cœur de la ligne de production se trouve la machine à mouler les plateaux à œufs, soutenue par des systèmes de pulpage, de séchage, de pressage à chaud et d'emballage pour garantir une production fluide et efficace.

Notre équipement a servi des clients dans des pays tels que le Nigeria, la Bolivie, le Cameroun, la Colombie, le Maroc et le Sri Lanka. Si vous envisagez de créer une entreprise de fabrication de plateaux à œufs, n'hésitez pas à nous contacter pour des solutions personnalisées !

Matières premières pour la ligne de production de plateaux à œufs

Les principales matières premières pour une usine de fabrication de plateaux à œufs sont le papier recyclé (comme le carton, les journaux, les livres et les magazines) et l'eau. Le papier recyclé doit être propre, exempt de contaminants et homogène en épaisseur.

Dans le processus de fabrication de la pâte, des produits chimiques tels que l'hydroxyde de sodium, le silicate de sodium et le sulfate d'aluminium sont ajoutés pour décomposer les fibres de papier, facilitant ainsi la formation des plateaux à œufs. L'utilisation de produits chimiques dépend du type de papier et de la qualité de produit requise.

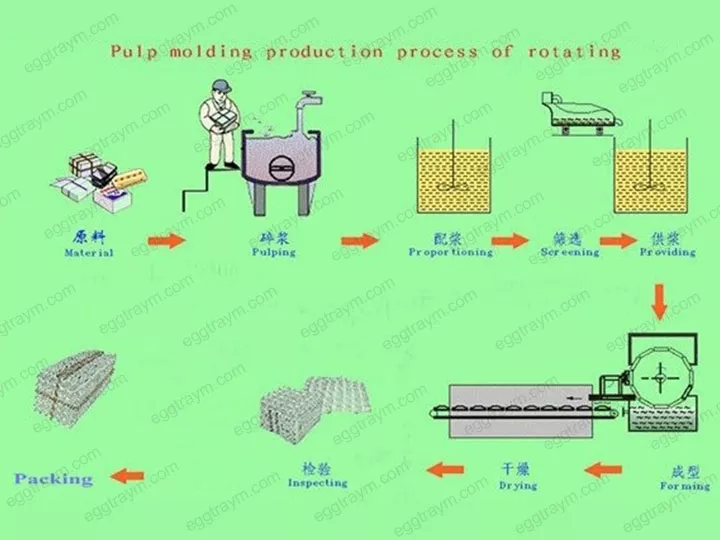

Flux de travail de l'usine de fabrication de plateaux à œufs

Le flux de travail principal d'une usine de fabrication de plateaux à œufs comprend quatre étapes clés : fabrication de pâte → moulage de pâte → séchage → emballage.

Les équipements impliqués comprennent généralement des pulpeurs à papier, des machines de formation de plateaux en papier, des séchoirs, des presses à chaleur et des machines d'emballage.

Selon la ligne de production, le processus de séchage peut utiliser des machines de séchage continu, des fours à briques ou un séchage à l'air naturel. Dans les installations semi-automatiques, le séchage, le pressage à chaud et l'emballage sont effectués manuellement.

Équipement principal de la ligne de production de plateaux en papier

L'équipement utilisé dans l'usine de fabrication de plateaux à œufs est capable de gérer de grands volumes de production de plateaux à œufs tout en maintenant la qualité et la cohérence du produit. Alors, quels sont les principaux équipements de la ligne de production de plateaux à œufs ?

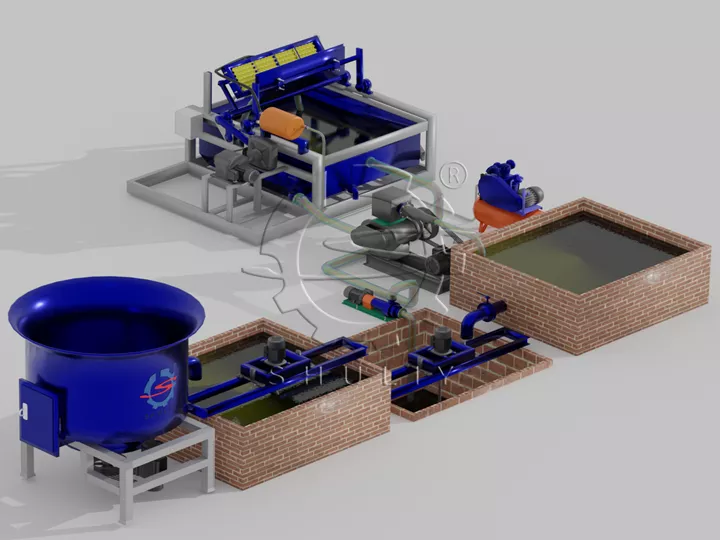

Machine à réduire en pâte

En règle générale, un seul travailleur est nécessaire pour mélanger les vieux papiers et l'eau dans un rapport de 1:3, le transformant ainsi en une pâte fine. Si un changement de couleur est souhaité, des colorants peuvent être introduits à ce stade.

Machine de formage de plateaux à œufs

Notre machine à barquettes à œufs est disponible en différents modèles, avec une capacité de production allant de 1500 à 8000 pièces par heure, vous permettant de choisir celle qui correspond à vos besoins. (Lire la suite : Machine à barquettes à œufs entièrement automatique à haute capacité>>) De plus, nous proposons des moules personnalisés, ce qui vous permet de les changer facilement à tout moment.

Sèche-linge

Après le démoulage, la barquette à œufs contient environ 30% d'eau, elle doit donc être séchée et durcie. Nous proposons différents types de séchoirs, y compris le séchage en four de brique et le séchage continu. Chaque méthode de séchage a son propre prix et son efficacité de production. (Article connexe : Machine de séchage de barquettes à œufs à séchage continu multi-couches>>)

Presse à chaud

La presse à chaud est efficace pour façonner davantage le plateau d'œufs séchés. Après avoir subi un traitement de pressage à chaud, le plateau à œufs devient plus résistant et plus défini.

Machine d'emballage

Les plateaux à œufs sont inspectés pour identifier tout défaut, notamment les fissures, la déformation et les surfaces inégales. Tous les plateaux défectueux sont jetés, tandis que les plateaux restants sont comptés, empilés et préparés pour la vente ou l'utilisation.

Paramètres complets de la ligne de production de cartons de papier

| Modèle | Capacité | Consommation de papier | Consommation d'eau | Énergie utilisée | Ouvrier |

| SL-3*1 | 1000-1500 pièces/heure | 120kg/heure | 300kg/heure | 32 kW/h | 3-4 |

| SL-4*1 | 1500-2000 pièces/h | 160kg/h | 380kg/h | 45 kW/h | 3-4 |

| SL-3*4 | 2000-2500 pièces/heure | 200kg/h | 450kg/h | 58 kW/h | 4-5 |

| SL-4*4 | 3000-3500 pièces/heure | 280kg/heure | 560kg/heure | 78 kW/h | 4-5 |

| SL-4*8 | 4000 pièces/heure | 320kg/heure | 600kg/heure | 80 kW/h | 5-6 |

| SL-5*8 | 5000 pièces/heure | 400kg/h | 750kg/h | 85 kW/h | 3-4 |

| SL-5*12 | 6000 pièces/heure | 480kg/heure | 900kg/h | 90 kW/h | 3-4 |

| SL-6*12 | 8000 pièces/heure | 640 kg/heure | 1040 kg/heure | 100 kW/h | 3-4 |

Avantages de la ligne de fabrication de plateaux à œufs en pâte à papier

- Assemblage d'équipement simple, facile à mettre en service, forte adaptabilité sur site.

- Le système de carburant est compatible avec plusieurs sources d'énergie, et seule l'électricité industrielle de 380V est requise pour l'alimentation.

- Le taux de rendement des plateaux en papier est stabilisé à plus de 99 %, et le taux d'intervention manuelle est réduit de 95 %.

- Adoption d'un séchage continu multi-couches, le temps de cycle est réduit à 1-2 heures, et la consommation d'énergie est considérablement réduite.

- La disposition verticale de la ligne de séchage multi-couches réduit l'espace occupé par rapport à la méthode de séchage naturel.

Pourquoi choisir notre usine de transformation de plateaux à œufs en pulpe ?

- Service attentif : réponse rapide, fournir des informations suffisantes pour vous aider à acheter en toute tranquillité.

- Sur mesure : personnaliser le plan de ligne de production optimal en fonction du budget, du site et de la production.

- Équipement durable : fabriqué avec des matières premières de haute qualité, longue durée de vie.

- Service après-vente sans souci : profitez d'un an de support après-vente, résolvez vos problèmes à temps.

Ligne de production de machines à plateaux à œufs vendue à la Colombie

Un client de Colombie, qui était novice en matière de machines à plateaux d'œufs, nous a contactés pour mettre en place sa première usine de fabrication de plateaux d'œufs. Pour les aider à comprendre les caractéristiques, notre commercial a partagé des images et des vidéos détaillées.

Nous avons ensuite fourni des spécifications pour tous les modèles disponibles, permettant au client de choisir celui qui correspond le mieux à ses besoins. Après une réflexion approfondie et des discussions avec son partenaire, ils ont décidé d'acheter une ligne de production complète de plateaux à œufs chez nous.

Comprendre le processus de fabrication des plateaux à œufs est essentiel pour choisir la machine appropriée. Si vous avez des questions concernant l'usine de fabrication de plateaux à œufs, veuillez soumettre votre demande en utilisant le formulaire de message à droite, et nous vous répondrons dans les 24 heures.