Machine à plateaux à œufs en pâte à papier expédiée avec succès à Oman

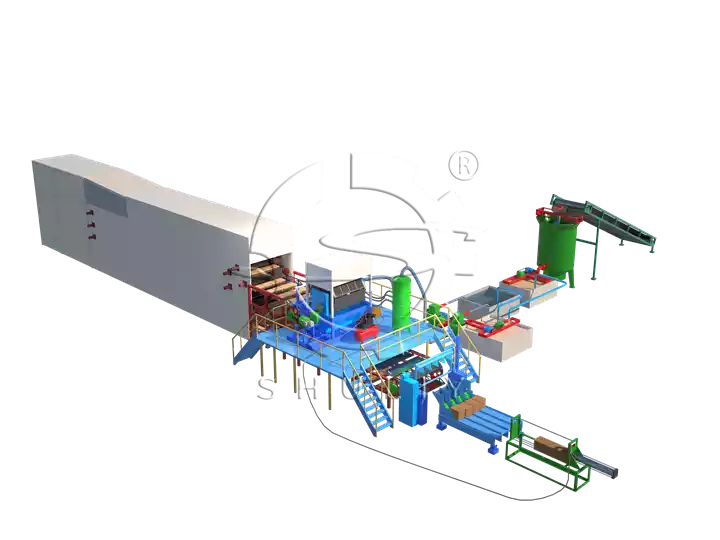

Nous sommes ravis d'annoncer que notre machine à plateaux à œufs en pâte à papier SL-3X1, spécialement conçue pour la production de plateaux à œufs en papier, a été expédiée avec succès à Oman.

Ce client d'Oman possède une riche expérience dans la fabrication de plateaux à œufs et nous a fourni des exigences claires et des informations précieuses concernant l'équipement nécessaire. Lors de nos premières discussions, le client a souligné ses attentes spécifiques concernant la capacité de production, la qualité du produit et le processus de production global.

Détails de la machine à plateaux à œufs en pâte à papier

Dans notre usine, nous respectons scrupuleusement les délais de production fixés par nos clients pour garantir que la machine soit terminée à la date convenue. Après avoir livré et mis en service avec succès la machine, le client a officiellement commencé à produire des plateaux à œufs en papier. Voici les détails de base de ce projet :

- Capacité : SL-3X1 produit 1 000 plateaux à œufs par heure.

- Produit final : plateaux à œufs réguliers à 30 compartiments.

- Méthode de séchage sur plateau à œufs : séchage naturel sous la lumière du soleil.

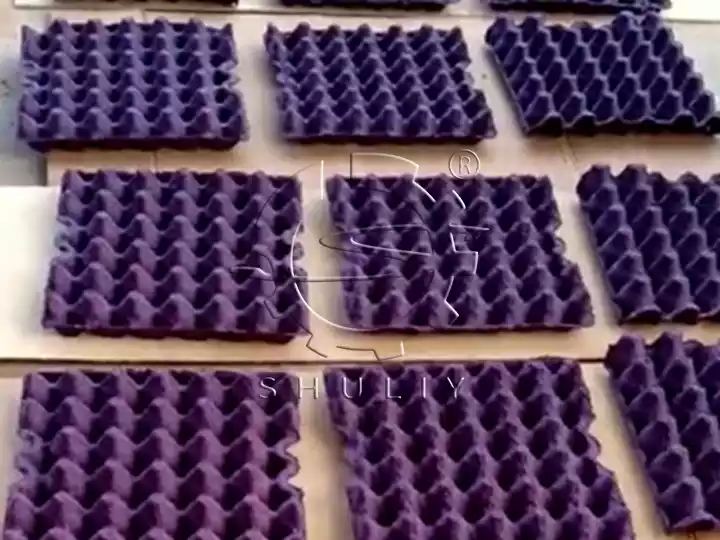

Personnalisation de la couleur du plateau à œufs

Le client a des exigences spécifiques concernant la couleur du plateau à œufs. Pour répondre à ces besoins personnalisés, notre équipe d'ingénieurs a fourni des conseils d'experts sur les additifs de couleur et les techniques d'ajustement, aidant ainsi le client à obtenir l'effet de couleur souhaité.

Une fois les plateaux à œufs produits, les ouvriers placent les plateaux humides sur des étagères et les déplacent vers un espace ouvert pour les sécher. Le temps de séchage peut varier en raison de facteurs naturels tels que la vitesse du vent et la température. Pour les clients qui souhaitent connaître le temps de séchage exact, notre société propose des canaux de consultation détaillés pour les tenir informés.

En tant que fabricant leader de machines à plateaux à œufs en pâte à papier, nous proposons une large gamme de modèles adaptés à vos besoins. (En savoir plus: Machine à plateaux à œufs entièrement automatique de grande capacité>>) Nous pouvons fournir des solutions sur mesure si vous avez besoin d'aménagements d'usine, de capacités de production, de compositions de matières premières, de spécifications finales de plateaux ou de méthodes de séchage spécifiques.

De plus, notre équipe peut envoyer des ingénieurs expérimentés sur votre site pour l'installation et la configuration de l'équipement. Si vous avez des questions ou des exigences, n’hésitez pas à nous contacter !