蛋托制造厂纸浆模塑机

| 模型 | SL-3*4 |

| 容量 | 2000-2500片/小时 |

| 纸张消耗量 | 200公斤/小时 |

| 用水量 | 450公斤/小时 |

| 使用的能源 | 58千瓦/小时 |

| 工人 | 4-5 |

您现在可以向我们的项目经理询问技术细节

该蛋托制造厂具有每小时1000-8000件的工业级生产能力和98%的原材料回收率,能够满足食品、医药和电子领域对减震保护的需求。

通过更换模具,您可以将废旧纸箱和报纸转化为各种托盘,例如蛋箱、彩色蛋托、苹果托和咖啡托,以满足全球市场的多样化需求。

生产线的核心是蛋托成型机,辅以制浆、干燥、热压和包装系统,以确保生产的顺利和高效。

我们的设备已为尼日利亚、玻利维亚、喀麦隆、哥伦比亚、摩洛哥和斯里兰卡等国家的客户提供服务。如果您考虑开始一个蛋托制造业务,请随时联系我们以获取定制解决方案!

蛋托生产线原料

蛋托制造厂的主要原材料是废纸(如纸板、报纸、书籍和杂志)和水。废纸应干净,无污染物,并且厚度要一致。

在造纸过程中,添加氢氧化钠、硅酸钠和硫酸铝等化学品,以分解纸纤维,从而提高成型蛋托的便利性。化学品的使用取决于纸张的类型和所需的产品质量。

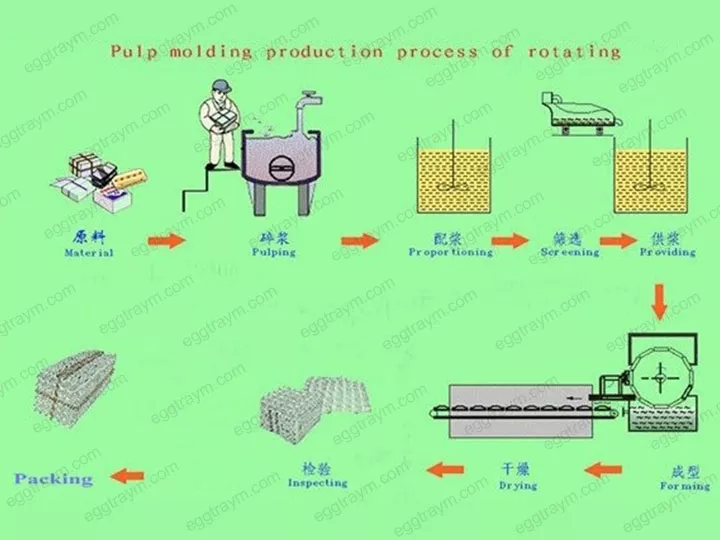

蛋托制造厂的工作流程

一个蛋托制造厂的主要工作流程包括四个关键步骤:制浆 → 成型 → 干燥 → 包装。

所涉及的设备通常包括纸浆机、纸托成型机、干燥机、热压机和包装机。

根据生产线的不同,干燥过程可能使用连续干燥机、砖窑或自然风干。在半自动化的设置中,干燥、热压和包装是手动完成的。

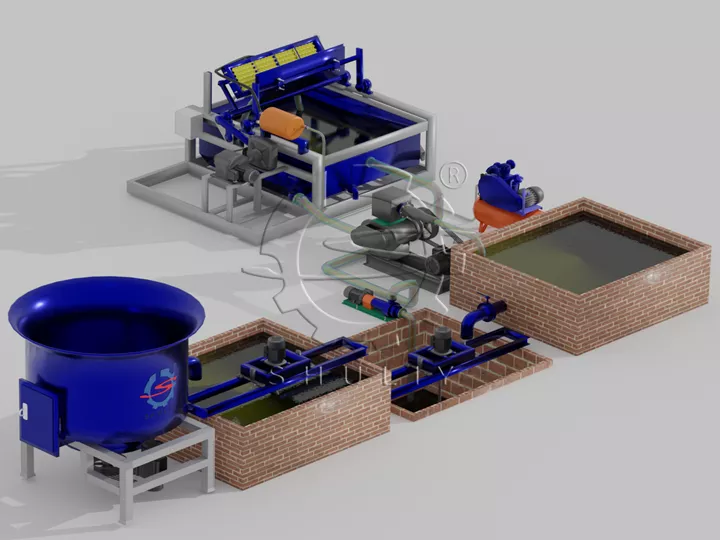

纸托生产线的主要设备

蛋托生产厂使用的设备能够在保持产品质量和一致性的同时,管理高产量的蛋托生产。那么,蛋托生产线中的关键设备有哪些呢?

制浆机

通常情况下,只需一名工人即可将废纸和水按照 1:3 的比例混合,将其变成细纸浆。如果需要改变颜色,可以在此阶段引入着色剂。

蛋托成型机

Our egg tray machine comes in various models, with an output ranging from 1500 to 8000 pieces per hour, allowing you to select one that fits your requirements. (Read more: Fully Automatic High Capacity Egg Tray Machine>>) Additionally, we offer customized molds, making it easy for you to switch them out whenever needed.

烘干机

在脱模后,蛋托含水量约为30%,因此需要进行干燥和固化。我们提供多种类型的干燥设备,包括砖窑干燥和连续干燥。每种干燥方式都具有相应的定价和生产效率。(相关帖子: 蛋托干燥机多层连续干燥设备>)

热压机

热压机可以有效地使干蛋托进一步成型。经过热压处理后,蛋托变得更加坚韧、轮廓更加分明。

包装机

蛋托经过检查以发现任何缺陷,包括裂纹、变形和不平整的表面。任何有缺陷的托盘都会被丢弃,而剩余的托盘则会被清点、堆放并准备出售或使用。

完整的纸箱生产线参数

| 模型 | 容量 | 纸张消耗量 | 用水量 | 使用的能源 | 工人 |

| SL-3*1 | 1000-1500片/小时 | 120公斤/小时 | 300公斤/小时 | 32千瓦/小时 | 3-4 |

| SL-4*1 | 1500-2000PCS/h | 160公斤/小时 | 380公斤/小时 | 45千瓦/小时 | 3-4 |

| SL-3*4 | 2000-2500片/小时 | 200公斤/小时 | 450公斤/小时 | 58千瓦/小时 | 4-5 |

| SL-4*4 | 3000-3500片/小时 | 280公斤/小时 | 560公斤/小时 | 78千瓦/小时 | 4-5 |

| SL-4*8 | 4000个/小时 | 320公斤/小时 | 600公斤/小时 | 80千瓦/小时 | 5-6 |

| SL-5*8 | 5000个/小时 | 400公斤/小时 | 750公斤/小时 | 85千瓦/小时 | 3-4 |

| SL-5*12 | 6000个/小时 | 480公斤/小时 | 900公斤/小时 | 90千瓦/小时 | 3-4 |

| SL-6*12 | 8000个/小时 | 640公斤/小时 | 1040公斤/小时 | 100千瓦/小时 | 3-4 |

纸浆蛋托生产线的优点

- 设备组装简单,易于投入使用,适应性强。

- 燃料系统兼容多种能源,仅需380V工业电力供电。

- 纸托的产量稳定在99%以上,人工干预率降低了95%。

- 采用多层连续干燥,循环时间缩短至1-2小时,能耗大幅降低。

- 多层干燥线的垂直布局相比自然干燥方法减少了占用空间。

为什么选择我们的纸浆蛋托加工厂?

- 贴心服务:快速响应,提供足够的信息帮助您安心购买。

- 量身定制:根据预算、场地和生产定制最佳生产线方案。

- 耐用设备:采用高质量原材料制造,使用寿命长。

- 无忧售后服务:享受一年的售后支持,及时解决您的问题。

蛋托机生产线销往哥伦比亚

一位来自哥伦比亚的客户,他对蛋托机不太了解,联系我们为他们建立第一家蛋托制造厂。为了帮助他们了解产品特性,我们的销售人员分享了详细的图片和视频。

然后我们提供了所有可用型号的规格,让客户选择最适合他们需求的产品。在与合作伙伴仔细考虑和讨论后,他们决定从我们这里购买一条完整的蛋托生产线。

了解蛋托生产过程对于选择合适的机器至关重要。如果您对蛋托生产厂有任何疑问,请使用右侧的留言表单提交您的咨询,我们将在24小时内回复您。