Mashine za Utengenezaji wa Sinia ya Mayai za Utengenezaji wa Mashine za Utengenezaji wa karatasi

| Mfano | SL-3*4 |

| Uwezo | 2000-2500pcs/h |

| Matumizi ya karatasi | 200kg/h |

| Matumizi ya Maji | 450kg/saa |

| Nishati iliyotumika | 58kw/saa |

| Mfanyakazi | 4-5 |

Sasa unaweza kuwauliza wasimamizi wetu wa mradi kwa maelezo ya kiufundi

Kiwanda cha kutengeneza tray za mayai chenye uwezo wa uzalishaji wa viwandani wa vipande 1000-8000 kwa saa + kiwango cha kurejeleza malighafi cha 98%, ambacho kinaweza kukidhi mahitaji ya ulinzi wa kupunguza mshtuko katika nyanja za chakula, dawa, na elektroniki.

Genom att byta formar kan du omvandla använda kartonger och tidningar till en mängd olika brickor, såsom äggkartonger, färgade äggbrickor, äppelbrickor och kaffebrickor, för att möta de olika behoven på den globala marknaden.

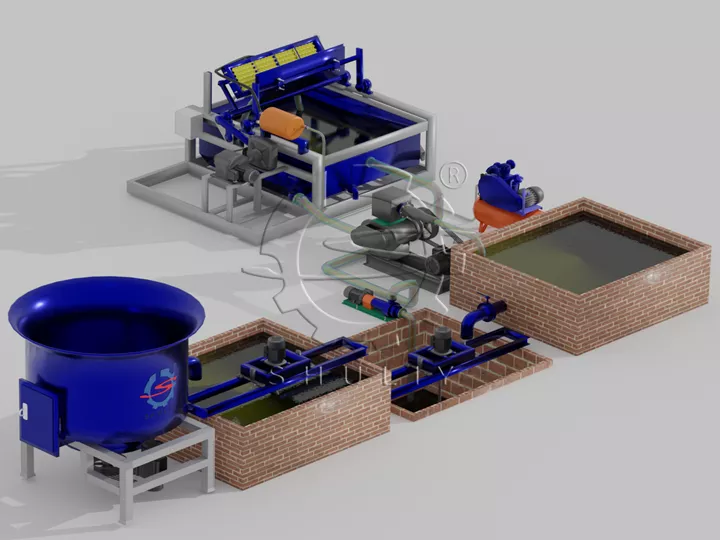

Katika moyo wa mchakato wa uzalishaji kuna mashine ya kutengeneza tray za mayai, inayoungwa mkono na mifumo ya kusaga, kukausha, kubana moto na kufunga ili kuhakikisha uzalishaji unakwenda vizuri na kwa ufanisi.

Vifaa vyetu vimehudumia wateja katika nchi kama Nigeria, Bolivia, Kamerun, Kolombia, Morocco na Sri Lanka. Ikiwa unafikiria kuanzisha biashara ya utengenezaji wa tray za mayai, tafadhali wasiliana nasi kwa suluhisho za kibinafsi!

Malighafi kwa mstari wa uzalishaji wa trei ya yai

Hamadraw material kwa kiwanda cha utengenezaji wa tray za mayai ni karatasi taka (kama vile kadi, magazeti, vitabu, na majarida) na maji. Karatasi taka inapaswa kuwa safi, isiyo na uchafu, na kuwa na unene sawa.

I utgörandet av massa tillsätts kemikalier som natriumhydroxid, natriumsilikat och aluminiumsulfat för att bryta ner pappersfibrerna, vilket underlättar bildandet av äggtråg. Användningen av kemikalier beror på typen av papper och den önskade produktkvaliteten.

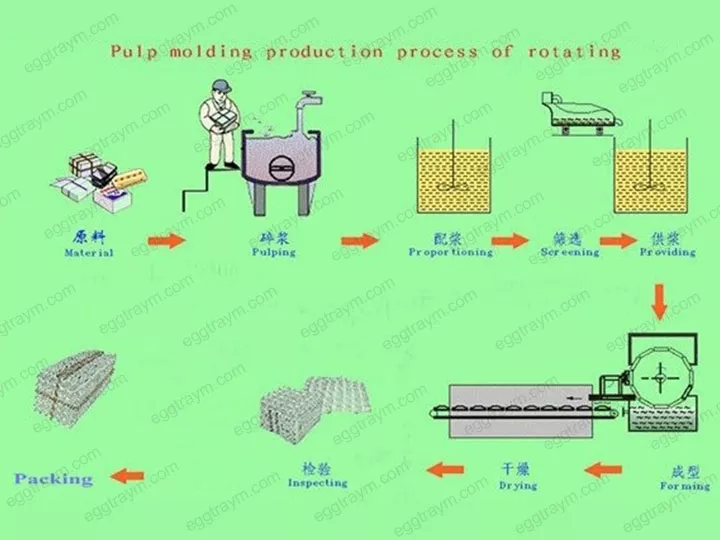

Mtiririko wa kazi wa kiwanda cha kutengeneza trei ya yai

Huvudarbetsflödet i en tillverkningsanläggning för äggkartonger inkluderar fyra nyckelsteg: pulpframställning → pulpformning → torkning → förpackning.

Utrustningen som vanligtvis ingår inkluderar papperspulperare, maskiner för formning av papperskartonger, torkare, värmepressar och förpackningsmaskiner.

Basi kwa laini ya uzalishaji, mchakato wa kukausha unaweza kutumia mashine za kukausha zinazoendelea, tanuru za matofali, au kukausha kwa hewa ya asili. Katika mipangilio ya nusu-automatik, kukausha, kubana moto, na kufunga hufanywa kwa mikono.

Huvudutrustning för pappersbricka produktionslinje

Vifaa vinavyotumika katika kiwanda cha utengenezaji wa tray za mayai vina uwezo wa kusimamia kiasi kikubwa cha uzalishaji wa tray za mayai huku vikiweka ubora na uthabiti wa bidhaa. Hivyo, ni vifaa gani muhimu katika mchakato wa uzalishaji wa tray za mayai?

Mashine ya kusukuma maji

Kwa kawaida, mfanyakazi mmoja tu anahitajika ili kuchanganya karatasi taka na maji kwa uwiano wa 1: 3, na kuifanya kuwa massa nzuri. Ikiwa mabadiliko ya rangi yanahitajika, rangi zinaweza kuletwa katika hatua hii.

Mashine ya kutengeneza trei ya mayai

Our egg tray machine comes in various models, with an output ranging from 1500 to 8000 pieces per hour, allowing you to select one that fits your requirements. (Read more: Fully Automatic High Capacity Egg Tray Machine>>) Additionally, we offer customized molds, making it easy for you to switch them out whenever needed.

Mashine ya kukausha

After demolding, the egg tray contains about 30% water, so it needs to be dried and cured. We offer various types of drying machines, including brick kiln drying and continuous drying. Each drying method comes with its own pricing and production efficiency. (Related Post: Egg Tray Dryer Multi-layer Continuous Drying Machine>>)

Mashine ya kushinikiza joto

Vyombo vya habari vya moto vina ufanisi katika kuunda zaidi tray ya yai kavu. Baada ya kufanyiwa matibabu ya vyombo vya habari vya moto, tray ya yai inakuwa kali na inaelezwa zaidi.

Mashine ya ufungaji

Trei za mayai hukaguliwa ili kubaini kasoro zozote, ikiwa ni pamoja na nyufa, mgeuko, na nyuso zisizo sawa. Trei zozote zenye kasoro hutupwa, huku zile zilizosalia zikihesabiwa, zimewekwa kwenye mrundikano, na kutayarishwa kwa ajili ya kuuzwa au kutumiwa.

Kamilisha vigezo vya mstari wa utengenezaji wa katoni za karatasi

| Mfano | Uwezo | Matumizi ya karatasi | Matumizi ya maji | Nishati iliyotumika | Mfanyakazi |

| SL-3*1 | 1000-1500pcs/h | 120kg/saa | 300kg/h | 32kw/saa | 3-4 |

| SL-4*1 | 1500-2000PCS/h | 160kg/h | 380kg/saa | 45kw/saa | 3-4 |

| SL-3*4 | 2000-2500pcs/h | 200kg/h | 450kg/saa | 58kw/saa | 4-5 |

| SL-4*4 | 3000-3500pcs/h | 280kg/saa | 560kg/saa | 78kw/saa | 4-5 |

| SL-4*8 | 4000pcs/h | 320kg/saa | 600kg/h | 80kw/saa | 5-6 |

| SL-5*8 | 5000pcs/h | 400kg/saa | 750kg/saa | 85kw/saa | 3-4 |

| SL-5*12 | 6000pcs/h | 480kg/saa | 900kg/saa | 90kw/saa | 3-4 |

| SL-6*12 | 8000pcs/h | 640kg/saa | 1040kg/saa | 100kw/saa | 3-4 |

Faida za mstari wa kutengeneza tray ya yai ya karatasi

- Enkel utrustningsmontering, lätt att sätta i bruk, stark platsanpassning.

- Bränslesystemet är kompatibelt med flera energikällor, och endast 380V industriell elektricitet krävs för strömförsörjning.

- Avkastningsgraden för papperskartonger stabiliseras på över 99%, och den manuella interventionsgraden minskas med 95%.

- Genom att använda flerlagers kontinuerlig torkning förkortas cykeltiden till 1-2 timmar, och energiförbrukningen minskas kraftigt.

- Den vertikala layouten av flerlagers torklinje minskar det utrymme som upptas jämfört med naturlig torkmetod.

Kwa nini uchague kiwanda chetu cha kusindika trei ya mayai ya majimaji?

- Omtänksam service: snabb respons, ge tillräcklig information för att hjälpa dig att köpa med sinnesro.

- Iliyoundwa maalum: badilisha mpango wa uzalishaji wa kipekee kulingana na bajeti, tovuti na uzalishaji.

- Vifaa vya kudumu: vinajengwa kwa malighafi za hali ya juu, maisha marefu ya huduma.

- Huduma ya baada ya mauzo isiyo na wasiwasi: furahia msaada wa mwaka mmoja baada ya mauzo, suluhisha matatizo yako kwa wakati.

Mashine ya kutengeneza trei ya mayai inauzwa Kolombia

Eine klant van Colombia, who was new to egg tray machines, reached out to us to set up their first egg tray manufacturing plant. To help them understand the features, our salesperson shared detailed pictures and videos.

Vi gav sedan specifikationer för alla tillgängliga modeller, vilket gjorde att kunden kunde välja den som passade bäst för deras behov. Efter noggrant övervägande och diskussion med sin partner beslutade de att köpa en komplett äggbricka produktionslinje från oss.

Kuelewa mchakato wa utengenezaji wa tray za mayai ni muhimu kwa kuchagua mashine inayofaa. Ikiwa una maswali yoyote kuhusu kiwanda cha utengenezaji wa tray za mayai, tafadhali wasilisha uchunguzi wako kwa kutumia fomu ya ujumbe upande wa kulia, na tutajibu ndani ya masaa 24.