Máquinas de moldagem de celulose para fábrica de bandejas de ovos

| Modelo | SL-3*4 |

| Capacidade | 2.000-2.500 unidades/h |

| Consumo de papel | 200kg/hora |

| Consumo de água | 450kg/hora |

| Energia utilizada | 58 kw/h |

| Trabalhador | 4-5 |

Agora você pode pedir detalhes técnicos aos nossos gerentes de projeto

A fábrica de fabricação de bandejas de ovos com capacidade de produção industrial de 1000-8000 peças/hora + taxa de reciclagem de matérias-primas de 98%, que pode atender à demanda por proteção contra choques nos campos de alimentos, medicina e eletrônicos.

Ao mudar os moldes, você pode converter caixas de papelão e jornais usados em uma ampla variedade de bandejas, como caixas de ovos, bandejas de ovos coloridas, bandejas de maçã e bandejas de café, para atender às diversas necessidades do mercado global.

No coração da linha de produção está a máquina de moldagem de bandejas de ovos, apoiada por sistemas de polpa, secagem, prensagem a quente e embalagem para garantir uma produção suave e eficiente.

O nosso equipamento tem servido clientes em países como Nigéria, Bolívia, Camarões, Colômbia, Marrocos e Sri Lanka. Se está a considerar iniciar um negócio de fabricação de bandejas de ovos, não hesite em contactar-nos para soluções personalizadas!

Matérias-primas para linha de produção de bandejas para ovos

As principais matérias-primas para uma fábrica de fabricação de bandejas de ovos são papel reciclado (como papelão, jornais, livros e revistas) e água. O papel reciclado deve estar limpo, livre de contaminantes e ter uma espessura consistente.

No processo de fabricação de polpa, são adicionados produtos químicos como hidróxido de sódio, silicato de sódio e sulfato de alumínio para decompor as fibras de papel, facilitando a formação de bandejas de ovos. O uso de produtos químicos depende do tipo de papel e da qualidade do produto exigida.

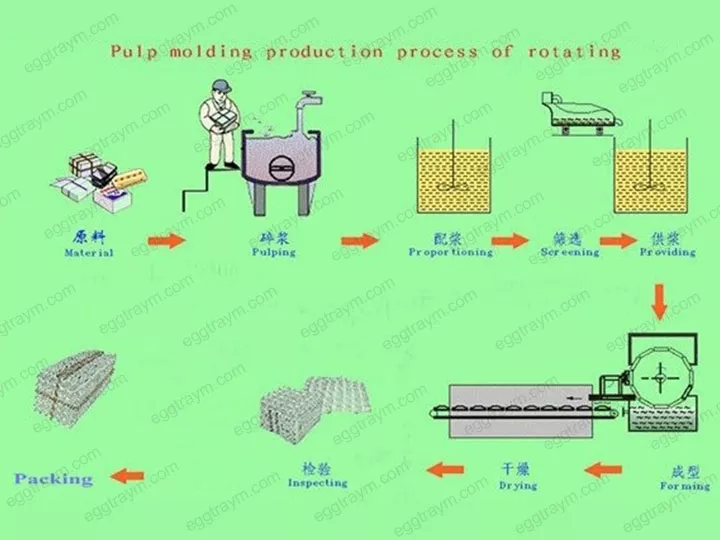

Fluxo de trabalho da fábrica de bandejas para ovos

O fluxo de trabalho principal de uma fábrica de fabricação de bandejas de ovos inclui quatro etapas principais: fabricação de polpa → moldagem de polpa → secagem → embalagem.

Os equipamentos envolvidos geralmente incluem desintegradores de papel, máquinas de moldagem de bandejas de papel, secadores, prensas térmicas e máquinas de embalagem.

Dependendo da linha de produção, o processo de secagem pode utilizar máquinas de secagem contínua, fornos de tijolo ou secagem ao ar natural. Em configurações semi-automáticas, a secagem, a prensagem a quente e a embalagem são feitas manualmente.

Equipamento principal da linha de produção de bandejas de papel

O equipamento utilizado na fábrica de produção de bandejas de ovos é capaz de gerir altos volumes de produção de bandejas de ovos, mantendo a qualidade e a consistência do produto. Então, quais são os principais equipamentos na linha de produção de bandejas de ovos?

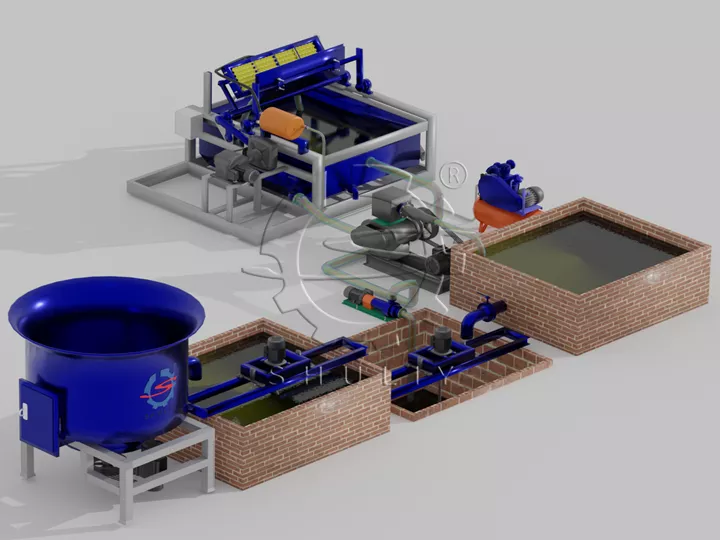

Máquina de polpação

Normalmente, é necessário apenas um trabalhador para misturar resíduos de papel e água na proporção de 1:3, transformando-os em uma polpa fina. Se for desejada uma mudança de cor, os corantes podem ser introduzidos nesta fase.

Máquina formadora de bandeja para ovos

Nossa máquina de tabuleiros de ovos vem em vários modelos, com uma produção que varia de 1500 a 8000 peças por hora, permitindo-lhe selecionar aquela que se adequa às suas necessidades. (Ler mais:Máquina de Tabuleiro de Ovos de Alto Sarge Automática Total>>) Além disso, oferecemos moldes personalizados, tornando fácil para si trocar sempre que necessário.

Máquina de secar

Depois de desmoldar, o tabuleiro de ovos contém cerca de 30% de água, por isso precisa de ser seco e curado. Oferecemos vários tipos de máquinas de secagem, incluindo secagem em forno de tijolos e secagem contínua. Cada método de secagem tem o seu próprio preço e eficiência de produção. (Artigo relacionado: Máquina de Secagem de Tabuleiro de Ovos de Múltiplas Camadas com Secagem Contínua>>)

Máquina de prensa térmica

A prensa quente é eficaz para moldar ainda mais a bandeja de ovos secos. Após passar pelo tratamento de prensagem a quente, a bandeja de ovos fica mais dura e definida.

Máquina de embalagem

As bandejas de ovos passam por inspeção para identificar quaisquer defeitos, incluindo rachaduras, deformações e superfícies irregulares. Quaisquer bandejas defeituosas são descartadas, enquanto as demais são contadas, empilhadas e preparadas para venda ou uso.

Parâmetros completos da linha de produção de caixas de papel

| Modelo | Capacidade | Consumo de papel | Consumo de água | Energia utilizada | Trabalhador |

| SL-3*1 | 1000-1500 unidades/h | 120kg/hora | 300kg/hora | 32 kw/h | 3-4 |

| SL-4*1 | 1500-2000 PCS/h | 160kg/hora | 380kg/hora | 45 kw/h | 3-4 |

| SL-3*4 | 2.000-2.500 unidades/h | 200kg/hora | 450kg/hora | 58 kw/h | 4-5 |

| SL-4*4 | 3000-3500 unidades/h | 280kg/hora | 560kg/hora | 78 kw/h | 4-5 |

| SL-4*8 | 4000 unidades/h | 320kg/hora | 600kg/hora | 80 kw/h | 5-6 |

| SL-5*8 | 5000 unidades/h | 400kg/hora | 750kg/hora | 85 kw/h | 3-4 |

| SL-5*12 | 6000 unidades/h | 480kg/hora | 900kg/hora | 90 kw/h | 3-4 |

| SL-6*12 | 8000 unidades/h | 640kg/hora | 1.040 kg/hora | 100 kw/h | 3-4 |

Vantagens da linha de fabricação de bandejas para ovos de polpa de papel

- Montagem simples de equipamentos, fácil de colocar em uso, forte adequação ao local.

- O sistema de combustível é compatível com várias fontes de energia, e apenas eletricidade industrial de 380V é necessária para o fornecimento de energia.

- A taxa de rendimento das bandejas de papel é estabilizada em mais de 99%, e a taxa de intervenção manual é reduzida em 95%.

- Adotando secagem contínua em múltiplas camadas, o tempo de ciclo é reduzido para 1-2 horas, e o consumo de energia é grandemente reduzido.

- O layout vertical da linha de secagem em múltiplas camadas reduz o espaço ocupado em comparação com o método de secagem natural.

Por que escolher nossa planta de processamento de bandejas para ovos de polpa?

- Serviço atencioso: resposta rápida, fornecendo informações suficientes para ajudá-lo a comprar com tranquilidade.

- Sob medida: personalizar o plano de linha de produção ideal de acordo com o orçamento, local e produção.

- Equipamento durável: construído com matérias-primas de alta qualidade, longa vida útil.

- Serviço pós-venda sem preocupações: desfrute de um ano de suporte pós-venda, resolva seus problemas a tempo.

Linha de produção de máquinas de bandejas para ovos vendida para a Colômbia

Um cliente da Colômbia, que era novo em máquinas de caixas de ovos, contactou-nos para montar a sua primeira fábrica de produção de caixas de ovos. Para os ajudar a compreender as funcionalidades, o nosso vendedor partilhou imagens e vídeos detalhados.

Em seguida, fornecemos especificações para todos os modelos disponíveis, permitindo que o cliente escolhesse o que melhor se adequava às suas necessidades. Após cuidadosa consideração e discussão com seu parceiro, decidiram comprar uma linha de produção completa de bandejas de ovos de nós.

Compreender o processo de fabricação de bandejas de ovos é essencial para selecionar a máquina apropriada. Se tiver alguma dúvida sobre a fábrica de fabricação de bandejas de ovos, por favor, envie sua consulta usando o formulário de mensagem à direita, e responderemos dentro de 24 horas.