Planta de fabricación de bandejas de huevos Máquinas de moldeo de pulpa de papel

| Modelo | SL-3*4 |

| Capacidad | 2000-2500 piezas/h |

| Consumo de papel | 200kg/h |

| Consumo de agua | 450kg/h |

| Energía utilizada | 58 kw/h |

| Obrero | 4-5 |

Ahora puede solicitar detalles técnicos a nuestros jefes de proyecto

La planta de fabricación de bandejas de huevos con una capacidad de producción industrial de 1000-8000 piezas/hora + una tasa de reciclaje de materias primas del 98%, que puede satisfacer la demanda de protección contra impactos en los campos de la alimentación, la medicina y la electrónica.

Al cambiar los moldes, puedes convertir cartones y periódicos usados en una amplia variedad de bandejas, como cartones de huevos, bandejas de huevos de colores, bandejas para manzanas y bandejas para café, para satisfacer las diversas necesidades del mercado global.

En el corazón de la línea de producción se encuentra la máquina de moldeo de bandejas de huevos, respaldada por sistemas de pulpa, secado, prensado en caliente y embalaje para garantizar una producción fluida y eficiente.

Nuestro equipo ha servido a clientes en países como Nigeria, Bolivia, Camerún, Colombia, Marruecos y Sri Lanka. Si está considerando iniciar un negocio de fabricación de bandejas para huevos, ¡no dude en contactarnos para soluciones personalizadas!

Materias primas para la línea de producción de bandejas de huevos.

Las principales materias primas para una planta de fabricación de bandejas de huevos son papel reciclado (como cartón, periódicos, libros y revistas) y agua. El papel reciclado debe estar limpio, libre de contaminantes y tener un grosor consistente.

En el proceso de fabricación de pulpa, se añaden productos químicos como hidróxido de sodio, silicato de sodio y sulfato de aluminio para descomponer las fibras de papel, mejorando la facilidad de formación de bandejas para huevos. El uso de productos químicos depende del tipo de papel y de la calidad del producto requerida.

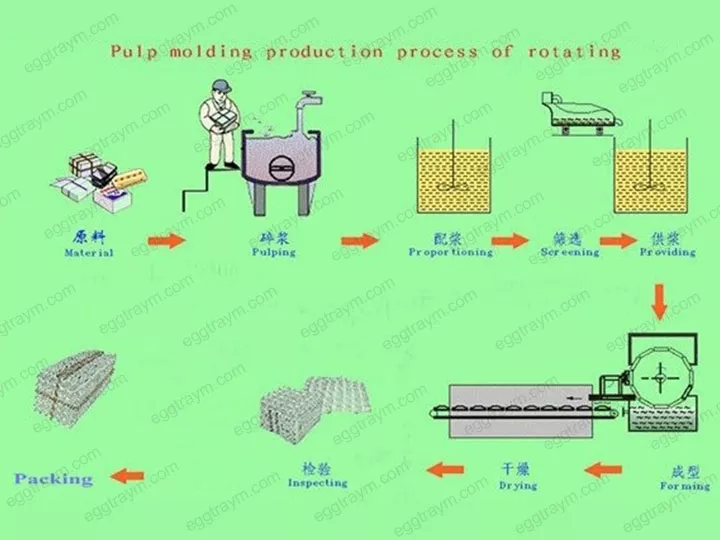

Flujo de trabajo de la planta de fabricación de bandejas de huevos.

El flujo de trabajo principal de una planta de fabricación de bandejas de huevos incluye cuatro pasos clave: fabricación de pulpa → moldeo de pulpa → secado → embalaje.

El equipo involucrado típicamente incluye pulpers de papel, máquinas formadoras de bandejas de papel, secadores, prensas de calor y máquinas de embalaje.

Dependiendo de la línea de producción, el proceso de secado puede utilizar máquinas de secado continuo, hornos de ladrillo o secado al aire natural. En configuraciones semiautomáticas, el secado, la prensado en caliente y el empaquetado se realizan manualmente.

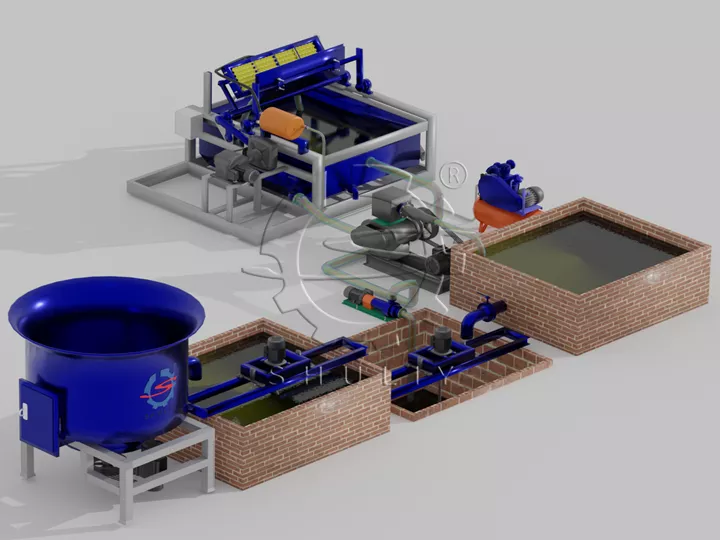

Equipo principal de la línea de producción de bandejas de papel

El equipo utilizado en la planta de fabricación de bandejas de huevos es capaz de manejar altos volúmenes de producción de bandejas de huevos mientras mantiene la calidad y consistencia del producto. Entonces, ¿cuáles son las piezas clave de equipo en la línea de producción de bandejas de huevos?

máquina despulpadora

Normalmente, solo se necesita un trabajador para mezclar papel usado y agua en una proporción de 1:3, convirtiéndolo en una pulpa fina. Si se desea un cambio de color, se pueden introducir colorantes en esta etapa.

Máquina formadora de bandejas de huevos

Nuestra máquina para bandejas de huevos viene en varios modelos, con una producción que oscila entre 1500 y 8000 piezas por hora, lo que le permite seleccionar una que se ajuste a sus necesidades. (Leer más: Máquina automática de bandejas de huevos de alta capacidad>>) Además, ofrecemos moldes personalizados, lo que facilita su cambio cuando sea necesario.

Secadora

Después del desmoldeo, la bandeja de huevos contiene aproximadamente un 30% de agua, por lo que necesita ser secada y curada. Ofrecemos varios tipos de máquinas de secado, incluido el secado en horno de ladrillos y el secado continuo. Cada método de secado tiene su propio precio y eficiencia de producción. (Publicación relacionada: Máquina de secado continuo multicapa para bandejas de huevos>>)

Máquina de prensa de calor

La prensa en caliente es eficaz para darle más forma a la bandeja de huevos secos. Después de someterse a un tratamiento de prensado en caliente, la bandeja de huevos se vuelve más dura y definida.

Maquina de empacado

Las bandejas de huevos se someten a una inspección para identificar cualquier defecto, incluidas grietas, deformaciones y superficies irregulares. Las bandejas defectuosas se descartan, mientras que las restantes se cuentan, apilan y preparan para su venta o uso.

Parámetros completos de la línea de producción de cartón de papel.

| Modelo | Capacidad | Consumo de papel | Consumo de agua | Energía utilizada | Obrero |

| SL-3*1 | 1000-1500 unidades/h | 120kg/hora | 300kg/h | 32 kw/h | 3-4 |

| SL-4*1 | 1500-2000PCS/h | 160kg/hora | 380kg/h | 45kw/h | 3-4 |

| SL-3*4 | 2000-2500 piezas/h | 200kg/h | 450kg/h | 58 kw/h | 4-5 |

| SL-4*4 | 3000-3500 piezas/h | 280kg/hora | 560kg/hora | 78 kw/h | 4-5 |

| SL-4*8 | 4000 piezas/h | 320kg/h | 600kg/hora | 80 kw/h | 5-6 |

| SL-5*8 | 5000 unidades/hora | 400kg/h | 750kg/hora | 85 kw/h | 3-4 |

| SL-5*12 | 6000 piezas/hora | 480kg/h | 900kg/hora | 90 kw/h | 3-4 |

| SL-6*12 | 8000 piezas/hora | 640kg/hora | 1040kg/hora | 100 kw/h | 3-4 |

Ventajas de la línea de fabricación de bandejas de huevos de pulpa de papel

- Montaje de equipo simple, fácil de poner en uso, fuerte adaptabilidad al sitio.

- El sistema de combustible es compatible con múltiples fuentes de energía, y solo se requiere electricidad industrial de 380V para el suministro de energía.

- La tasa de rendimiento de las bandejas de papel se estabiliza en más del 99%, y la tasa de intervención manual se reduce en un 95%.

- Adoptando un secado continuo de múltiples capas, el tiempo de ciclo se reduce a 1-2 horas, y el consumo de energía se reduce considerablemente.

- La disposición vertical de la línea de secado de múltiples capas reduce el espacio ocupado en comparación con el método de secado natural.

¿Por qué elegir nuestra planta procesadora de bandejas de pulpa de huevos?

- Servicio atento: respuesta rápida, proporciona información suficiente para ayudarte a comprar con tranquilidad.

- Hecho a medida: personaliza el plan óptimo de línea de producción de acuerdo con el presupuesto, el sitio y la producción.

- Equipos duraderos: fabricados con materias primas de alta calidad, larga vida útil.

- Servicio postventa sin preocupaciones: disfruta de un año de soporte postventa, resuelve tus problemas a tiempo.

Línea de producción de máquinas para bandejas de huevos vendida a Colombia

Un cliente de Colombia, que era nuevo en las máquinas para bandejas de huevos, se puso en contacto con nosotros para montar su primera planta de fabricación de bandejas de huevos. Para ayudarles a comprender las características, nuestro comercial compartió imágenes y vídeos detallados.

Luego proporcionamos especificaciones para todos los modelos disponibles, permitiendo al cliente elegir el que mejor se adapte a sus necesidades. Después de una cuidadosa consideración y discusión con su socio, decidieron comprar una línea de producción completa de bandejas de huevos de nosotros.

Entender el proceso de fabricación de bandejas de huevos es esencial para seleccionar la máquina adecuada. Si tiene alguna pregunta sobre la planta de fabricación de bandejas de huevos, envíe su consulta utilizando el formulario de mensaje a la derecha, y responderemos dentro de 24 horas.