蛋托生产线的工作流程是怎样的?

无论是半自动还是全自动蛋托生产线,它们的工作流程都类似。成品没有区别,只有工作速度的不同。为了让客户更清楚地了解我们的蛋托机的工作流程,本文将详细介绍。如果您有其他问题,请随时与我们联系!

蛋托生产线包括哪些机器?

半自动纸质蛋托生产线:打浆机,蛋托成型机,干燥机。

全自动蛋托生产线:纸张粉碎机,蛋托机,干燥机(砖窑干燥,金属干燥机),热压机,打包机,堆垛机.

完整的蛋托生产线的工作步骤

1. 碎浆机

无论生产线是半自动还是全自动,都包括纸浆机。打浆机是一种专门用于制作蛋托原材料的机器。将废纸 scraps 等原材料放入打浆机中,加入水和其他原材料并将其打成浆。这一过程相当于回收那些使用过的纸 scraps。它是将它们重新制作成蛋托的一步.

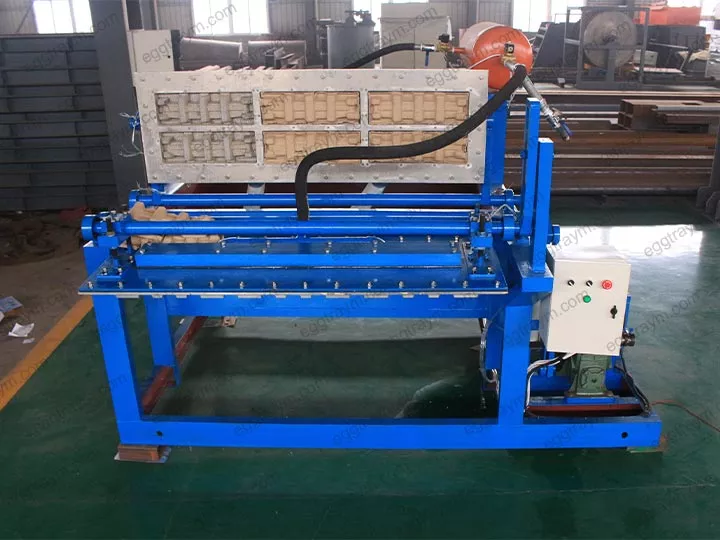

2、蛋托机

本机是制作蛋托的机器。成品浆通过管道输送至蛋托机。蛋托机上可以安装不同的模具。不同的模具可以制作不同款式的蛋托。客户还可以使用同一台机器,通过更换不同的模具,生产苹果托盘、酒托盘等工业包装。整形成功后,蛋盘还是湿的。

3. 烘干机

湿蛋托需要通过人工干燥、砖干燥线或金属干燥机进行干燥。通常,大产量的蛋托生产线配备有蛋托干燥机。多层金属蛋托干燥机可以处理多批次蛋托。金属干燥机占地小,产生均匀的热量,受到许多客户的欢迎.

4.热压机

热压机是通过加热模具使干燥后的蛋托进一步塑化。热压后的蛋托更加美观、耐用。

5. 包装机

以节省储存空间,方便搬运和运输。工人将热压好的蛋托穿过包装机,将蛋托压紧。这样,蛋盘就会叠在一起。打好的蛋盘被送往各大养鸡场、商场、超市,实现其价值。

这就是全自动蛋托生产线的工作流程。半自动蛋托生产线通常采用人工日晒风干的方式进行干燥。之后,所有蛋盘均由人工处理。

我们会根据客户的具体情况推荐合适的蛋托机生产线组合。需要考虑的因素包括客户的预算、工厂规模、可用燃料、天气、劳动力投入等。