Kwa nini Kampuni za Ufungaji Zinapanua Mistari Yao ya Utengenezaji wa Mifuko ya Karatasi?

Moja ya faida kubwa za mistari ya uzalishaji wa tray za karatasi ni upatikanaji wa malighafi nyingi, za bei nafuu. Karatasi taka kutoka kwa sanduku za katoni, magazeti ya zamani, vipande vya vitabu, tray za mayai zilizorejelewa, na taka nyingine za karatasi zote zinaweza kutumika kama malighafi kuu.

Rahisi sana changanya vifaa hivi na maji kwa viwango sahihi ili kuzalisha pulp kwa haraka. Hii siyo tu inapunguza gharama za uzalishaji bali pia inalingana na mwelekeo wa mazingira wa dunia, ikileta faida kubwa zaidi kwa biashara.

Mifumo mitatu kuu kwa umbo thabiti

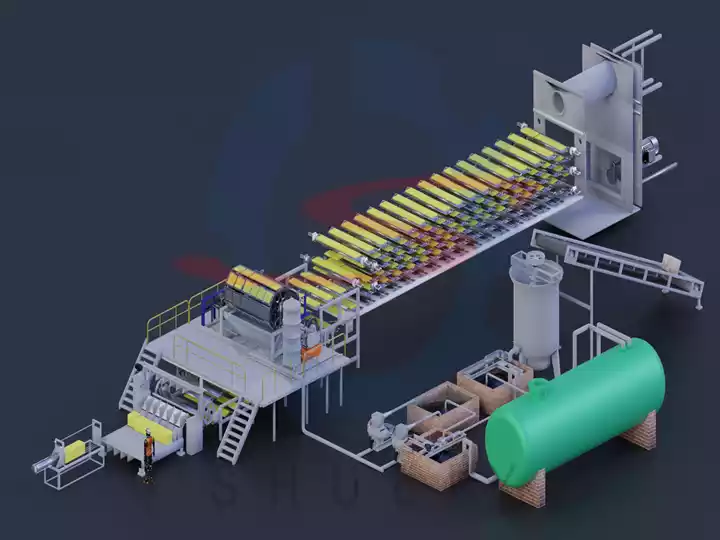

Mstari wa uzalishaji wa tray za karatasi unajumuisha mfumo wa kuchakata, mfumo wa umbo, na mfumo wa kukausha, kila hatua imeboreshwa kwa ufanisi:

- Mfumo wa kuchakata huharakisha mchakato wa kuchakata karatasi taka kuwa pulp sare, nyembamba kwa kutumia hydraulic pulper, pampu ya pulp, na refiner, kuweka msingi wa umbo unaofuata.

- Mfumo wa umbo hutumia mvutano wa hewa kuhamisha pulp kwenye miundo, kuunda tray za mvua kwa haraka. Maji ya ziada yanarejeshwa na mfumo wa mvutano, kuongeza matumizi ya rasilimali za maji.

- Mfumo wa kukausha hutoa chaguzi zinazobadilika kulingana na uzalishaji na bajeti—kukua kwa hewa asilia, kukausha kwa tanuru ya matofali, au mistari kamili ya kukausha ya chuma—kuhakikisha bidhaa zinaweka na kuunda kwa muda mfupi huku zikihifadhi ubora wa mara kwa mara.

Njia hii ya uzalishaji wa kuunganisha sana inaharakisha umbo wa tray za mayai na kuongeza usawa wa bidhaa, ikifanya iweze kwa mashirika ya ukubwa tofauti.

Chaguzi nyingi za miundo kwa bidhaa tofauti za tray

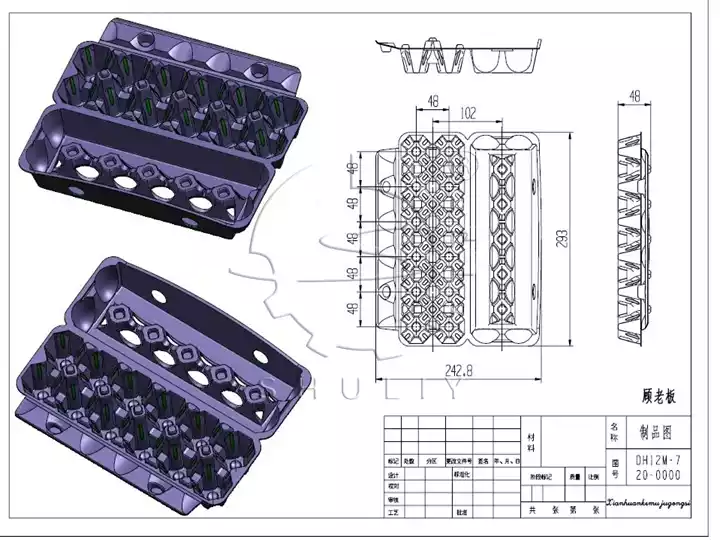

Ili kukidhi matumizi tofauti ya wateja, mstari wa usindikaji wa tray za karatasi unaunga mkono chaguzi nyingi za miundo:

- Miundo ya plastiki inatoa gharama ya chini na utulivu wa umbo, inayofaa kwa uzalishaji wa aina nyingi za bidhaa.

- Miundo ya alumini inatoa upinzani wa kutu na maisha marefu, ikiwa na miundo inayoweza kubadilishwa kwa masoko ya juu.

Kama unavyotengeneza tray za mayai, tray za matunda, vichwa vya vikombe, au kifurushi cha kinga cha viwandani, kubadilisha haraka modeli kunaboresha matumizi ya vifaa.

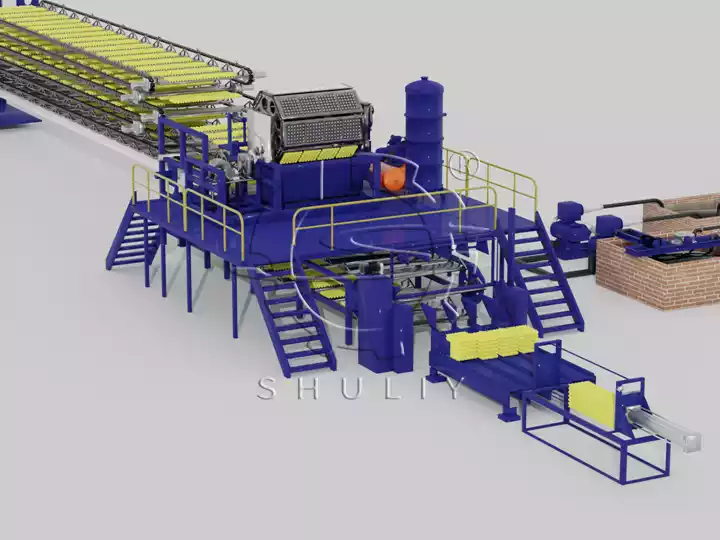

Miundo miwili ya mstari wa uzalishaji wa tray za karatasi

- Mifano kamili ya otomatiki inafaa kwa viwanda vikubwa vinavyotumia kitufe kimoja, kuruhusu maandalizi ya pulp, umbo, kukausha, na kuweka kwa otomatiki ili kupunguza sana gharama za kazi.

- Mfano wa semi-automated unafaa kwa mashirika madogo hadi ya kati yenye ufanisi wa gharama kubwa, yanahitaji msaada wa mikono kwa sehemu.

Haijalishi ukubwa wa bajeti, mashirika yanaweza kupata suluhisho linalofaa.

Hitimisho

Kadri nchi zaidi zinavyotekeleza marufuku ya plastiki, bidhaa za kutengeneza kwa mchakato wa karatasi zinajitokeza kama mbadala mkuu wa kifurushi cha plastiki. Mistari ya uzalishaji wa tray za karatasi inatoa matumizi ya chini ya nishati, gharama za uendeshaji za chini, na thamani kubwa ya mazingira, ikileta matarajio mazuri ya soko na faida za uwekezaji.

Ikiwa ungependa maelezo zaidi kuhusu uwezo wa uzalishaji, usanidi, bei, au una maswali mengine, tafadhali jisikie huru kuwasiliana nasi wakati wowote. Tutahakikisha tunakupatia suluhisho bora zaidi la uzalishaji wa tray za karatasi.