5 ключевых причин выбрать яичную лоток, образуя производственную линию

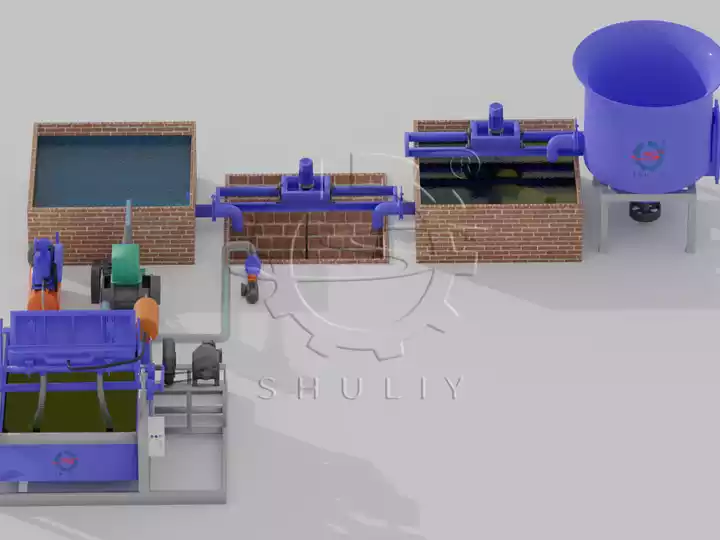

В упаковке яиц птицы яичные лотки защищают безопасность свежих яиц, а их эффективность производства и качество напрямую влияют на преимущества цепочки поставок. Перед лицом рыночного спроса на защиту окружающей среды, высокой эффективности и интеллектуального модернизации, производственная линия, формирующая яичное лоток, имеет пять основных преимуществ, чтобы стать предпочтительным решением отрасли для обновления.

Отличная производственная мощность

- Быстрая скорость формирования и высокая стабильность может реализовать производство тысяч до десятков тысяч яичных лотков в час, ежедневная выработка легко превышает 50 000 лотков.

- Идеально удовлетворяет потребности крупномасштабных ферм, сети супермаркетов, сельскохозяйственных продуктов и т. Д., Для больших количеств яичных лотков.

- Автоматизированная передача, сушка, упаковка и другие ссылки плавно, весь производственный процесс работы сборочной линии, значительно снижая человеческую ошибку и интенсивность труда.

Энергетическая экономия и защита окружающей среды

- Современная линия производства яичного лотка оптимизирована при переработке воды, рециркуляции водой, в сушке отходов, и т. Д. Потребление воды и потребление энергии могут быть уменьшены на более чем 30%, что помогает предприятиям снизить производственные затраты.

- Сточные воды в процессе производства целлюлозы переработаны посредством многоэтапной обработки, а остаток отходов может использоваться в качестве городского озеленения или топлива для биомассы после сушки и сжатия, реализуя «нулевое выброс» и «нулевые отходы».

Превосходное качество яичных лотков

- Процесс формования точно контролируется, толщина стенки яичного лотка распределена равномерно, и она была протестирована путем сброса и сжатия, с превосходной способностью против шока и анти-переходов, что гарантирует, что яйца не повреждены и не повреждены во время транспортировки, хранения и других аспектов.

- Готовые изделия имеют гладкую поверхность без заусенцев, без запаха, без вредных остатков вещества, и они прошли ряд тестирования и сертификации пищевых продуктов, что добавляет точки к изображению бренда.

Гибкий и диверсифицированный

- Производственная линия, образующая яичную лоток, поддерживает быстрое изменение плесени, адаптировано к различным спецификациям коробка для яиц (например, яйца, утиные яйца, перепелиные яйца), без необходимости масштабного времени простоя и гибкой реакции на изменения рынка.

- Производители предоставляют универсальный сервис от выбора, установки, ввода в эксплуатацию, обучения по техническому обслуживанию, резерв запасных частей, быстрой скорости ответа.

Интеллектуальный контроль над производственной линией для яичного лотка

Оснащенный системой управления ПЛК, настройка параметров, тревога с ошибкой и мониторинг работы и эксплуатацию ясны, упрощают сложность обучения оператора.

Независимо от того, строите ли вы новый завод или модернизируете существующую линию по производству формованных лотков для яиц, эти инвестиции снизят затраты и повысят эффективность вашего бизнеса. Свяжитесь с нами сегодня, чтобы получить индивидуальные решения и возможность протестировать оборудование!