Кыргызстан вводит линию для производства поддонов из целлюлозы для повышения автоматизации производства.

Местная компания по производству экологически чистой упаковки в Кыргызстане долгое время полагалась на традиционные методы производства яичных поддонов, которые требовали высокой трудоемкости и приводили к низкой производительности и растущим затратам на труд. Компании срочно нужна высоко интегрированная, надежная автоматизированная линия для производства яичных поддонов из целлюлозы, чтобы оптимизировать численность персонала, увеличить производственные мощности и снизить операционные расходы.

Цель проекта клиента

- Основная цель клиента при модернизации оборудования заключалась в увеличении уровня автоматизации как минимум на 50% от существующей производственной базы.

- Необходимо было обеспечить плавный переход от формовки яичных лотков, сушки и сбора.

- В то же время необходимо обеспечить непрерывность и стабильность производственного процесса, чтобы удовлетворить потребности в доставке крупных заказов и поддержать долгосрочное устойчивое развитие.

Индивидуальное решение для линии по производству яичных поддонов из целлюлозы

Команда Shuliy провела несколько раундов технической коммуникации с клиентом в Кыргызстане, чтобы понять их производственные узкие места и потребности в автоматизации.

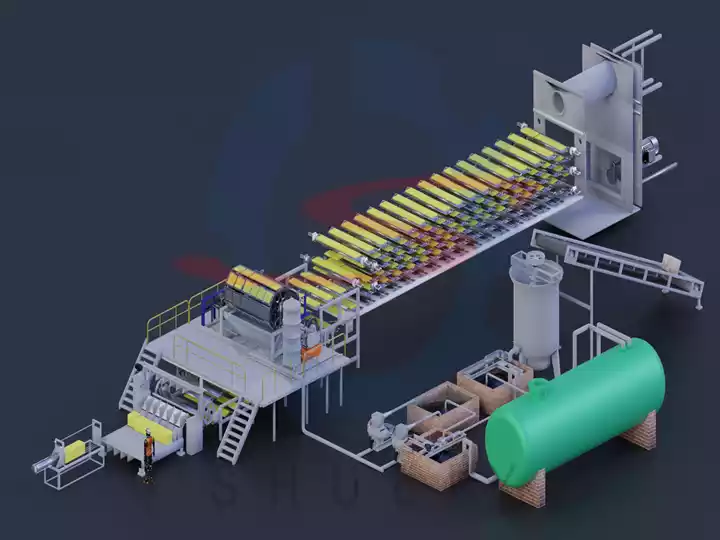

Основываясь на беспокойствах клиента по поводу стабильности оборудования, простоты эксплуатации и последующих затрат на обслуживание, мы предложили линию для производства ячеек для яиц SL4-1 в качестве основы, вместе с полностью автоматизированной системой непрерывной сушки и устройством для сбора и палетирования поддонов, чтобы улучшить общую эффективность обработки.

Детали конфигурации проекта производственной линии

Заказчик в итоге решил внедрить производственную линию яичных лотков SL4-1 со следующей конфигурацией:

- Производственная мощность: 1500 подносов для яиц в час

- Количество форм: 4 барабана, 1 конфигурация формовочной головки

- Сырьё: макулатура

- Тип готового продукта: бумажный поднос для яиц

- Дополнительное оборудование: автоматическая система непрерывной сушки металла, автоматическая система сбора лотков

- Установка: техническое руководство и установка инженерами Shuliy на месте

В настоящее время производственная линия яичных лотков успешно установлена и введена в эксплуатацию в Кыргызстане.

Вся линия обеспечивает эффективное использование ресурсов отходов бумаги благодаря высокоавтоматизированным системам подготовки целлюлозы, формования, сушки и укладки. Это не только значительно повышает производственную эффективность и однородность продукции, но и эффективно снижает неопределенность, вызванную ручной работой.