Bisakah Saya Memulai Bisnis Produksi Baki Telur Dengan Investasi Kecil?

Dengan meningkatnya kesadaran lingkungan dan pembatasan terhadap produk plastik, baki telur pulp telah menjadi tren pasar. Bisnis produksi baki telur skala kecil yang terjangkau tidak hanya cocok untuk pengusaha tetapi juga memungkinkan pengembalian investasi cepat dan keuntungan stabil.

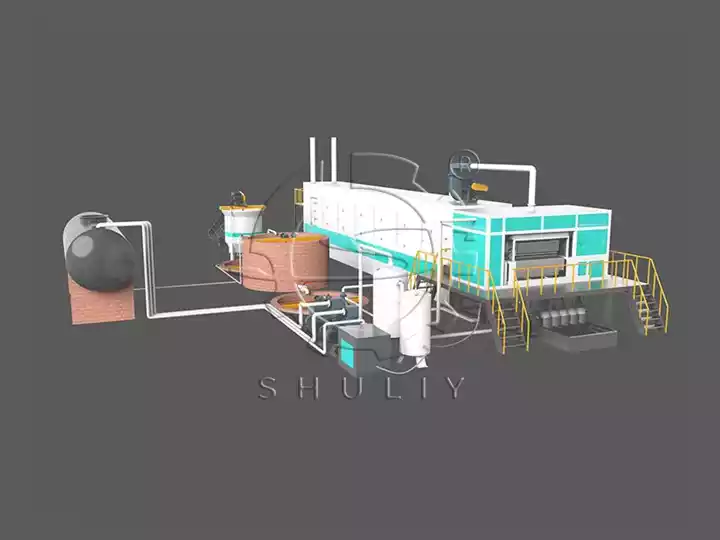

Produksi efisien dengan investasi minimal

- Investasi fleksibel: total investasi untuk jalur produksi baki telur kecil berkisar sekitar $50.000 hingga $80.000 USD. Model dapat dipilih berdasarkan kapasitas produksi yang dibutuhkan.

- Output yang dapat dikendalikan: mesin kecil tunggal memproduksi 1.000–2.000 baki per jam, sementara model yang lebih besar mencapai 3.000–7.000 baki/jam.

- Operasi yang ramah pengguna: sistem kontrol PLC dengan fungsi otomatisasi pengisian, pembentukan, dan dewatering memungkinkan penguasaan cepat bahkan untuk pemula.

Bahkan startup atau bengkel kecil dapat mencapai produksi otomatis melalui investasi strategis, meningkatkan output dan profitabilitas.

Bahan biaya rendah untuk bisnis produksi baki telur

- Bahan yang tersedia dengan mudah: limbah kertas, koran lama, buku bekas, dan kotak kardus bekas semuanya berfungsi sebagai bahan baku yang layak.

- Biaya rendah: limbah kertas biaya serendah ¥0–500/ton, dengan sumber daya air didaur ulang, secara signifikan mengurangi biaya produksi.

- Manfaat lingkungan: tidak ada emisi berbahaya selama produksi. Baki telur 100% dapat terurai secara hayati, membuatnya lebih disukai pasar dibandingkan baki plastik.

Melalui daur ulang kertas limbah, pengusaha tidak hanya mengurangi biaya tetapi juga sejalan dengan kebijakan lingkungan, mencapai produksi hijau.

Kustomisasi yang fleksibel dan produk yang beragam

- Mampu memproduksi baki telur 24/30/6/12 untuk memenuhi berbagai permintaan pelanggan.

- Cukup ganti cetakan untuk memproduksi baki dengan ukuran atau bentuk berbeda, cocok untuk telur ayam, bebek, burung puyuh, dll.

- Line produksi dapat diperluas untuk memproduksi kotak kertas, baki bibit tanaman, atau baki medis, memperluas aplikasi pasar.

Produk yang beragam dan pertukaran cetakan memungkinkan jalur produksi beradaptasi dengan pasar multifaset, meningkatkan daya saing perusahaan.

Kesimpulan

Line proses bisnis produksi baki telur yang ringkas menawarkan investasi rendah, bahan ramah lingkungan, dan output efisien tinggi. Melalui kustomisasi yang fleksibel dan produksi yang beragam, memastikan profitabilitas yang stabil sambil sejalan dengan tren keberlanjutan lingkungan. Pilih kami sebagai mitra ideal Anda untuk investasi kewirausahaan.