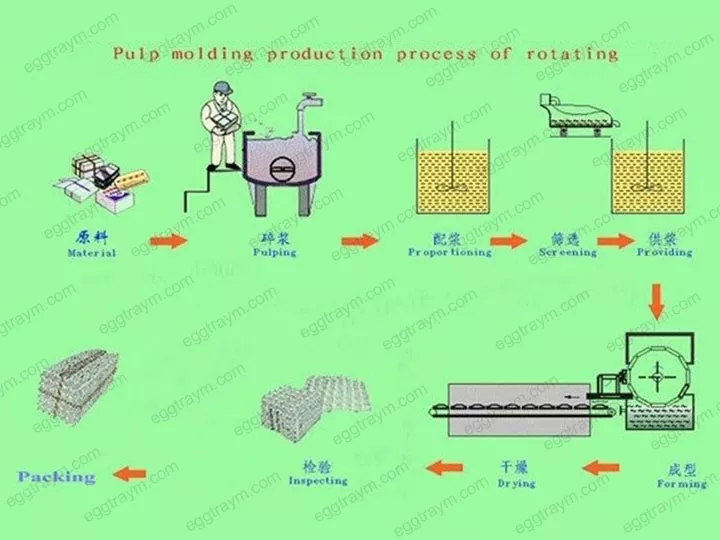

Cara Membuat Pulp Di Pabrik Pembuatan Baki Telur

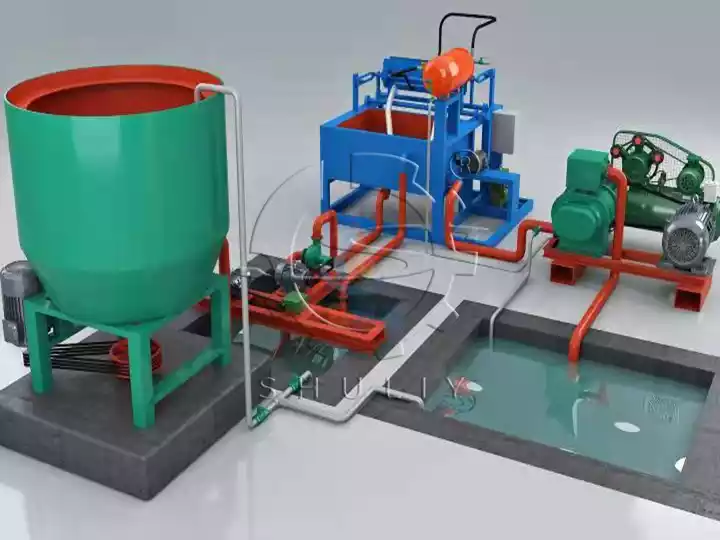

Dalam lini produksi tray telur, operasi efisien dari mesin pulp kertas sangat penting untuk efisiensi keseluruhan, dan perannya yang utama adalah mengubah kertas bekas menjadi pulp untuk menyediakan bahan baku dasar untuk proses pencetakan tray telur berikutnya.

Bahan Baku Pulper

Produksi baki telur pada dasarnya merupakan proses daur ulang kertas bekas. Jadi sumber pulpnya adalah lembaran kertas bekas, kertas kemasan kotak, dan sebagainya. Bahan baku yang lebih besar tidak cocok untuk diakses langsung ke mesin pulp, sehingga perlu dioperasikan dengan bantuan mesin penghancur terlebih dahulu.

Cara Membuat Bubur Kertas

- Perendaman Kertas Limbah: Pertama, kertas bekas yang terkumpul dimasukkan ke dalam tangki perendaman untuk direndam. Proses ini membantu melunakkan kertas dan membuatnya lebih mudah terurai.

- Penghancuran Pulp: Setelah direndam, kertas bekas dipecah dan dipecah dengan cermat hingga membentuk bahan berserat halus. Ini adalah langkah penting dalam penyiapan pulp, memastikan kertas bekas tersebar dengan baik.

- Membentuk Pulp: Setelah direndam dan dihaluskan, kertas bekas diubah menjadi pulp yang mengandung serat halus, kelembapan, dan komponen kertas lainnya. Langkah ini dirancang untuk menyediakan bahan baku yang homogen untuk proses pencetakan selanjutnya.

Proses pembuatan bubur kertas menggunakan bahan kertas bekas dengan biaya lebih rendah dan memungkinkan daur ulang sumber daya, sehingga secara efektif mengurangi tekanan terhadap eksploitasi sumber daya hutan. Selain itu, proses ini memastikan ketebalan dan kekokohan baki telur yang seragam, sehingga meningkatkan kualitas produk secara keseluruhan.