How to Choose an Egg Tray Making Machine? 5 Key Points All You Need to Know

Egg tray making machines have become essential investment equipment for poultry farms, packaging plants, and recycling enterprises. Choosing the right equipment ensures stable production capacity and controllable costs; selecting the wrong one not only delays delivery schedules but may also drag down profits long-term. Below, we outline the key logic for selecting egg tray machines from a practical perspective.

Production capacity matching

The production capacity of an egg tray making machine directly determines investment scale and payback period.

- 1,000–3,000 trays/hour: suitable for small-scale farms or pilot ventures.

- 4,000–7,000 trays/hour: meets stable supply needs with optimal cost-effectiveness.

- 8,000+ trays/hour: suitable for large-scale factories or export orders.

Experience shows that blindly pursuing high capacity often leads to increased energy consumption and idle costs. Matching capacity to actual order volume ensures faster payback.

Machine automation level

The difference between semi-automatic and fully automatic systems extends beyond price to long-term operational costs:

- Semi-automatic lines typically require 4–6 operators.

- Fully automated egg tray lines require only 1–2 personnel for supervision.

- Higher automation ensures greater consistency in forming, reducing scrap rates by 20%–30%.

For long-term operations, fully automated configurations are more conducive to cost reduction and efficiency gains.

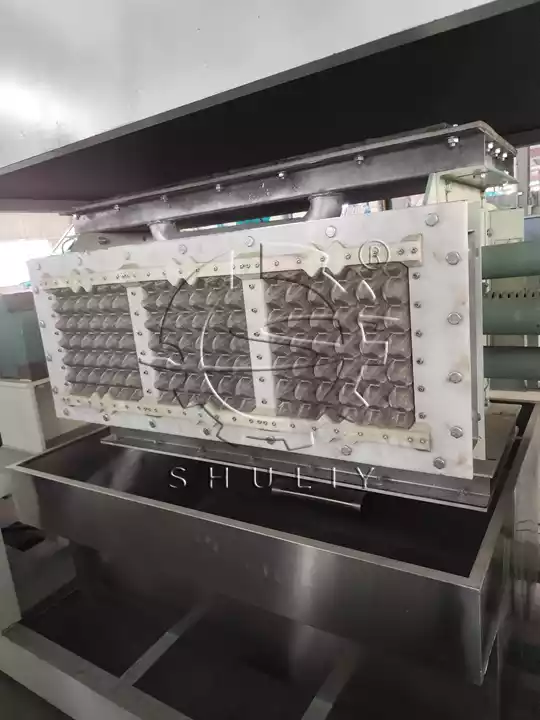

Core components

The true determinants of egg tray making machine lifespan and product quality lie in core components:

- Sturdy forming host structure enables continuous operation up to 20 hours/day.

- High-precision metal molds deliver service life exceeding 5 years.

- Multi-layer hot-air drying system boosts drying efficiency by 30%–40%.

- Stainless steel in critical areas ensures effective corrosion resistance and easy cleaning.

Robust configuration translates to fewer downtimes and higher effective output.

Energy consumption & Raw material utilization

In egg tray production, energy consumption and waste paper utilization represent significant hidden costs:

- Energy-efficient motors + variable frequency control reduce electricity consumption by 10%–15%.

- High-efficiency dehydration and forming reduce drying load.

- Improved product yield saves tens of thousands of yuan in raw material costs annually.

Manufacturer and service

Egg tray machines are not disposable equipment; after-sales service is equally critical:

- Does the manufacturer provide installation, commissioning, and operator training?

- Are spare parts standardized and supplied promptly?

- Do molds support multi-specification expansion (egg trays, fruit trays, cup trays, etc.)?

Reliable manufacturers often ensure equipment operates continuously and stably for 5–10 years.

Conclusión

Choosing an egg tray making machine isn’t just about selecting equipment—it’s about choosing a reliable partner. Our factory boasts years of experience in R&D and manufacturing of egg tray machines, offering on-site installation and commissioning, operator training, and long-term spare parts supply.

Whether you’re starting small-scale production or scaling up for large-volume manufacturing, we provide customized solutions that deliver high output, stability, and energy efficiency. Invest with confidence and achieve a smooth return on your investment.