تم شحن خط معالجة صينية البيض SL-3*4 إلى روسيا لتقليل تكاليف الاستيراد

أخبار رائعة! لقد تم شحن خط معالجة قشور البيض SL-3*4 الكامل إلى روسيا. العميل هو مؤسسة زراعية كبيرة تعمل في إنتاج الأعلاف وتربية الدواجن. مع سنوات من الخبرة في تغذية الحيوانات والزراعة المستدامة، لا يقتصر الأمر على تزويد المزارعين المحليين بأعلاف عالية الجودة فحسب، بل يدير أيضًا عدة مزارع دواجن. تنتج هذه المزارع إمدادًا ثابتًا من البيض الطازج الذي يتطلب تعبئة مستمرة.

تحديات وأهداف العميل

في السابق، كان العميل يعتمد بشكل كبير على استيراد علب البيض، مما أدى إلى تكاليف لوجستية عالية وسلسلة إمداد غير مستقرة، خاصة خلال مواسم الإنتاج الذروة. للحفاظ على الربحية وضمان موثوقية التعبئة، قرر العميل الاستثمار في إنشاء خط إنتاج علب بيض محلي.

كان الهدف الرئيسي للعميل هو إنشاء خط معالجة قشور بيض داخلي قادر على تلبية احتياجات تعبئة مزارع الدواجن الخاصة بهم مع توفير فائض من الصناديق للمزارع المجاورة. هدفت هذه المبادرة إلى تقليل التكاليف التشغيلية، وتحسين اتساق التعبئة، وتوليد إيرادات إضافية من خلال المبيعات المحلية.

حل خط معالجة صينية البيض

تواصل معنا العميل عبر موقعنا الرسمي بحثًا عن حلول موثوقة وفعالة لتشكيل اللب. بعد مناقشات فنية مفصلة وتحليل الإنتاج، قدمنا حلاً شاملاً ومخصصًا.

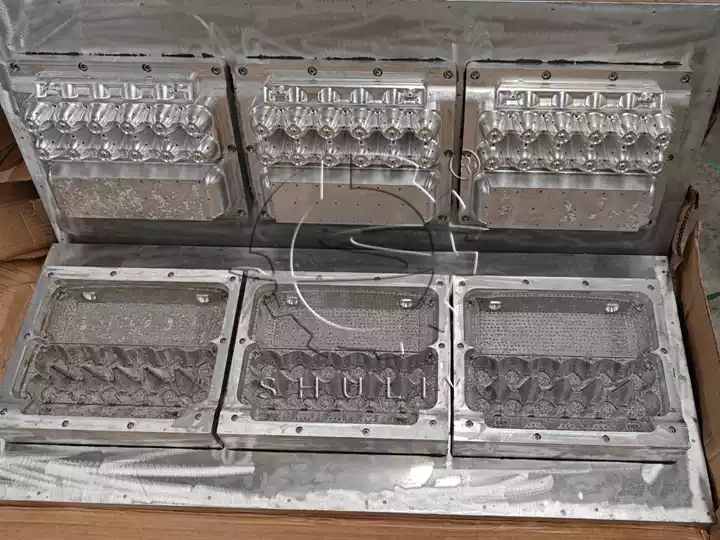

توصية النموذج

استنادًا إلى قدرة الإنتاج ومتطلبات الإنتاج اليومي للعميل، توصي مجموعة شوللي باستخدام آلة تشكيل قشور البيض SL-3*4. يمكن لهذا النموذج إنتاج 2000-2500 صينية بيض في الساعة. معروف بأدائه المستقر، وسهولة الاستخدام، وطول عمر الخدمة، وهو خيار مثالي للمزارع المتوسطة الحجم ومصانع تعبئة البيض المحلية.

تعزيز الكفاءة

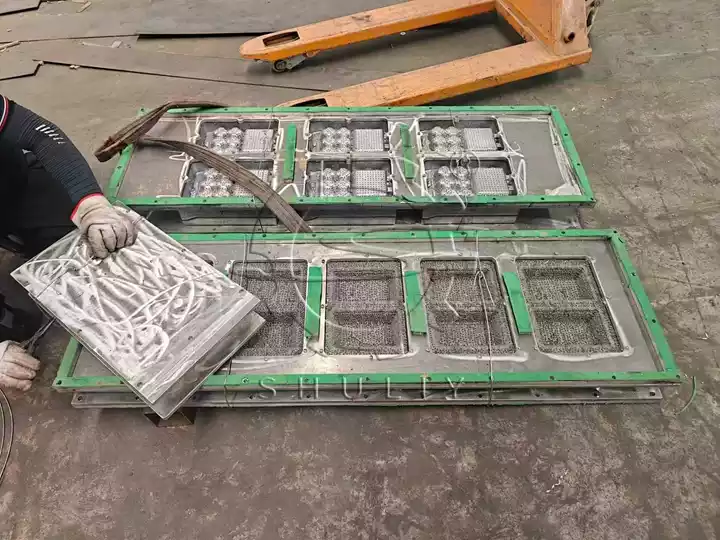

لضمان إنتاجية عالية في ظل ظروف المناخ المتغيرة في روسيا، زودنا خط الإنتاج بنظام تجفيف معدني. بالمقارنة مع التجفيف الطبيعي التقليدي، يقلل المجفف المعدني بشكل كبير من وقت التجفيف، مما يضمن استمرارية الإنتاج دون تأثر بالظروف الجوية.

ترقية الأتمتة

لتبسيط التعامل والتعبئة بعد التشكيل، يدمج خط الإنتاج معدات جمع وتكديس قشور البيض الآلية. هذا النظام الآلي لا يقلل فقط من كثافة العمل ولكنه يعزز أيضًا نظافة مكان العمل وكفاءة التنظيم.

النتائج المحققة

تم تركيب خط معالجة قشور البيض SL-3*4خط معالجة قشور البيض المصبوب من اللببنجاح وهو الآن يعمل في منشأة عميل روسي. تشمل الإنجازات الرئيسية:

- سعة عالية: عند التشغيل بكامل طاقته، يحقق الخط إنتاجًا سنويًا قدره 21 مليون صينية بيض.

- خفض التكاليف: أزال العميل الاعتماد على استيراد علب البيض، مما خفض بشكل كبير تكاليف الإنتاج واللوجستيات.

- نمو الأرباح: حقق العميل إيرادات جديدة من خلال بيع فائض من قشور البيض للمزارع المجاورة، مع دعم التنمية الزراعية المحلية في الوقت نفسه.

لأي استفسارات، لا تتردد في الاتصال بنا. نحن مستعدون لتقديم عرض حل تنافسي لك.