كيف يمكن لآلة صينية البيض تحقيق إنتاج فعال ومنخفض التكلفة؟

بفضل سياسة "الورق مقابل البلاستيك"، أصبحت صواني البيض المصنوعة من اللب خيارًا رئيسيًا لتعبئة البيض. كالمعدات الأساسية في خطوط إنتاج تشكيل اللب، يتم اعتماد آلات صينية البيض بشكل متزايد من قبل المزارع وشركات التعبئة نظرًا لنتائج التشكيل المستقرة وسعة الإنتاج عالية الكفاءة.

ثبات الهيكل الأساسي يضمن جودة التشكيل

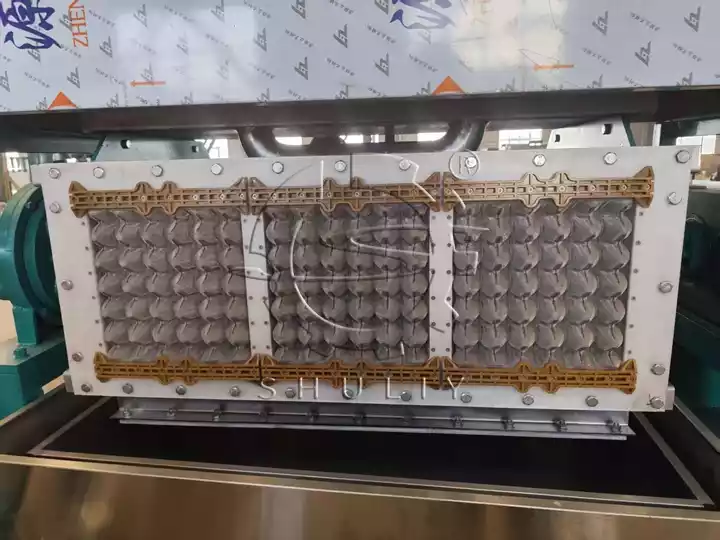

تستخدم آلات صينية البيض عملية تشكيل بالشفط باستخدام قوالب علوية وسفلية. من خلال الشفط بالفراغ والتشكيل بالضغط، يتم تشكيل لب الورق المهمل بسرعة إلى صواني بيض موحدة.

تتميز سطح القالب بشبكة معدنية تحتوي على فتحات شفط اللب موزعة بشكل موحد، مما يضمن ترسيب ألياف اللب بشكل متساوٍ. يؤدي ذلك إلى سمك منتظم لصينية البيض وحواف حادة ومحددة.

يسهل تصميم الآلة المدمج استبدال القوالب، مما يجعلها مناسبة للإنتاج المستمر على المدى الطويل. يظل معدل نجاح التشكيل ثابتًا فوق 95%.

كفاءة إنتاج عالية لمعالجة على نطاق واسع

تمكن آلات صينية البيض الأوتوماتيكية من التشغيل المستمر من خلال عمليات شفط اللب، والتشكيل، وإزالة القالب، والنقل، مع مدة دورة تشكيل واحدة تتراوح بين 3 إلى 7 ثوانٍ تقريبًا.

اعتمادًا على التكوين، يتراوح الإنتاج من 2000 إلى 6000 صينية في الساعة. يمكن لخطوط الإنتاج الكبيرة أن تتوسع إلى أكثر من 10000 صينية في الساعة، مما يقلل بشكل فعال من تكاليف العمالة ويزيد من السعة الإجمالية.

مرونة التكيف مع المواصفات المتعددة للتطبيقات المرنة

عن طريق تبديل القوالب، تنتج الآلة صواني لـ 6، 10، 12، 15، أو 30 بيضة، لتلبية مختلف الأحجام بما في ذلك بيض الدجاج، البط، والإوز.

بالإضافة إلى صواني البيض، يمكنها توسيع الإنتاج ليشمل صواني الفاكهة، حوامل الأكواب، صواني الشتلات، وغيرها من المنتجات المصنوعة من اللب المعالج، مما يتيح استخدامًا متعدد الأغراض ويعظم استغلال المعدات.

آلة صينية البيض الصديقة للبيئة على نطاق واسع

صواني البيض المصنوعة من الورق المهمل قابلة للتحلل الحيوي وقابلة لإعادة التدوير، مما يتماشى مع اتجاهات التعبئة الخضراء. مقارنة بالتعبئة البلاستيكية، يمكن تقليل تكاليف المواد الخام بنسبة 20% إلى 40%.

حاليًا، يتم نشر آلات صنع صواني البيض على نطاق واسع في مرافق إنتاج البيض، ومصانع التعبئة الغذائية، ومراكز التوزيع اللوجستية.

لا توفر صواني البيض المصنوعة من اللب فقط توسيدًا ممتازًا وامتصاصًا للصدمات، بل تدعم أيضًا التصاميم المخصصة. يعزز ذلك جمالية تغليف المنتج مع تلبية متطلبات السوق المتنوعة.

هل تريد معرفة المزيد عن الآلة؟ انقر هنا: آلة صينية البيض الأوتوماتيكية عالية السعة. لا تتردد في الاتصال بنا في أي وقت.